Introduction

Inventory management is a critical component of successful businesses around the globe.

By optimizing their inventory processes, companies can boost their efficiency, reduce costs, and increase customer satisfaction.

This comprehensive section dives deep into real-world examples of inventory management, showcasing how various organizations have implemented innovative strategies to overcome challenges and achieve their business objectives.

Amazon: Mastery of Inventory Management Through Technology

Amazon stands as a paragon of inventory management excellence, leveraging advanced technologies to streamline its operations.

Let’s discover the key strategies Amazon employs to maintain operational excellence and customer satisfaction.

Dynamic Inventory Allocation

Amazon employs a dynamic approach to inventory allocation, which allows for flexible distribution of products across its extensive network of fulfillment centers.

By leveraging advanced algorithms and real-time data, Amazon can quickly respond to changes in demand, ensuring products are strategically located closer to customers.

Benefits:

- Reduced shipping times and costs.

- Enhanced ability to manage demand surges.

- Improved customer satisfaction through reliable and rapid delivery services.

Just-In-Time (JIT) Inventory System

Amazon employs a JIT strategy to minimize excess inventory and reduce related costs. Products are received only as needed for order fulfillment, which helps maintain competitive pricing and maximize profit margins.

Benefits:

- Lower inventory holding costs.

- Reduced risk of overstocking and obsolescence.

- Enhanced flexibility in inventory management.

Advanced Forecasting Techniques

Amazon harnesses the power of big data and machine learning to predict demand for millions of products with remarkable accuracy.

Benefits:

- Optimized inventory levels, avoiding overstock and stockouts.

- Improved efficiency in inventory replenishment.

- Enhanced ability to adjust to market trends and consumer preferences rapidly.

Multi-Tier Inventory Management

Amazon has implemented a complex, multi-tier inventory management system that includes Amazon-owned inventory, third-party sellers, and dropshipping arrangements.

Benefits:

- Vast product selection without significant inventory risk.

- Flexibility to scale inventory based on demand.

- Reduced storage and handling costs through third-party seller and dropshipping models.

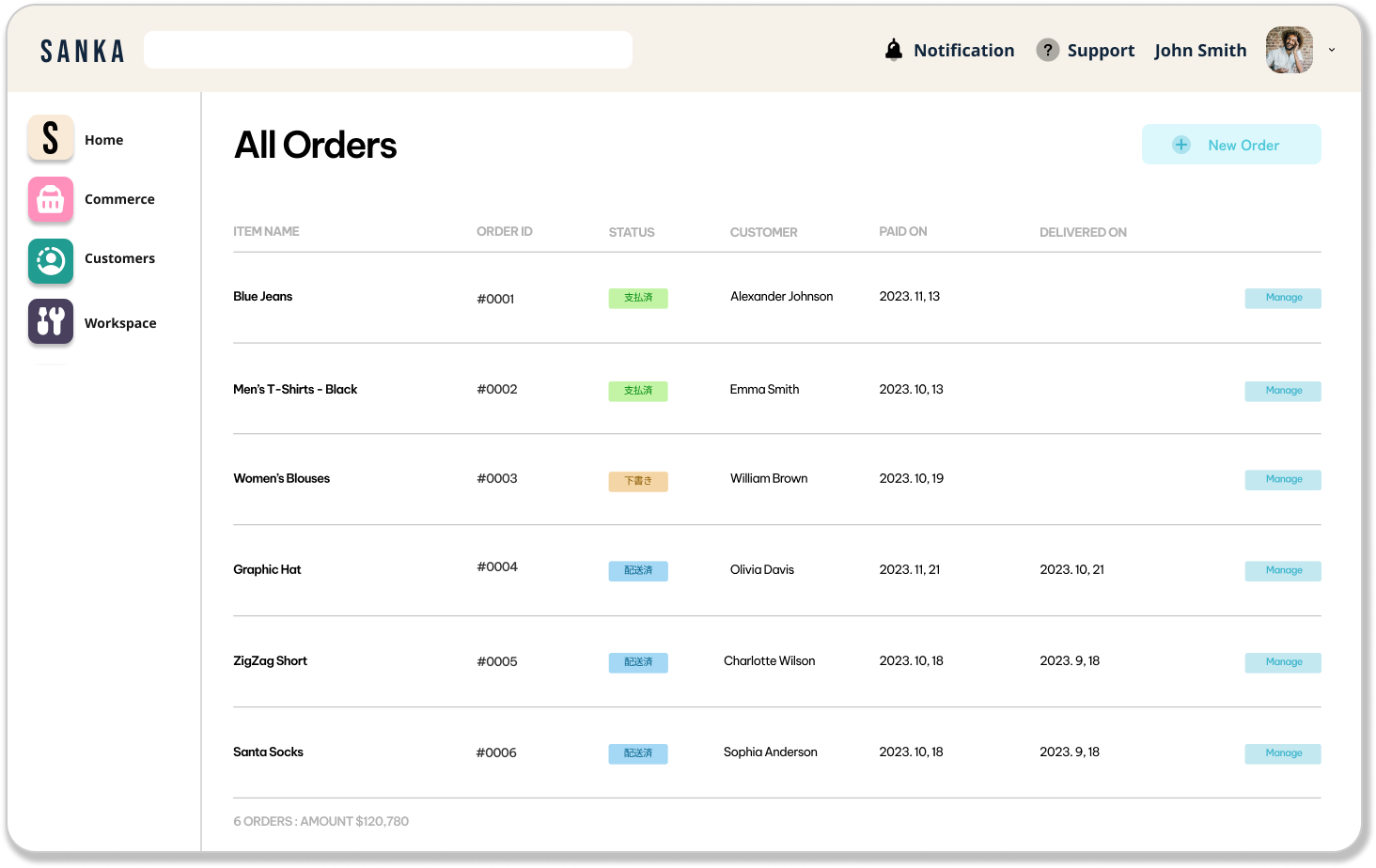

Robotic Process Automation (RPA)

In its fulfillment centers, Amazon utilizes RPA and advanced robotics to automate various inventory management tasks.

Benefits:

- Enhanced operational efficiency and accuracy.

- Reduced labor costs and human error.

- Improved capacity to handle high order volumes, especially during peak periods.

Data-Driven Decision Making

Amazon's inventory management is underpinned by a data-driven culture.

Every decision, from stock levels to warehouse locations, is informed by data analysis, ensuring that strategies are aligned with current market dynamics and customer expectations.

Benefits:

- Informed decision-making that optimizes inventory efficiency. Enhanced customer satisfaction by meeting demand.

- Ability to quickly adapt to market changes and consumer trends.

By adeptly managing inventory across its vast network of fulfillment centers, Amazon achieves extraordinary efficiency in order processing and delivery.

This high level of inventory optimization allows Amazon to offer services like same-day or two-day shipping for Prime members, a significant competitive advantage that has contributed greatly to its customer satisfaction and loyalty.

Walmart: Pioneering the Retail Link System

Walmart, the world’s largest retailer, has revolutionized inventory management with its Retail Link System.

This system provides real-time data to suppliers about the sales of their products in Walmart stores and warehouses.

Suppliers can access detailed reports and analyses on inventory levels, allowing them to restock products efficiently and effectively.

The Retail Link system functions as an integrated tool allowing for high levels of cooperation and synchronization between Walmart and its suppliers. Here’s how it operates:

Real-Time Data Access

Supplies and vendors have access to real-time sales data for their products in Walmart stores.

This access allows suppliers to monitor how their products are performing across different regions and during various periods.

Demand Forecasting

Using sophisticated algorithms, Retail Link helps predict future product demands based on historical sales data, seasonal trends, and other market influences.

This predictive capability allows suppliers to plan production and shipments more accurately, minimizing the risk of stockouts or excess inventory.

Automated Replenishing

One of the key features of Retail Link is its ability to automate replenishment orders.

When inventory levels drop below a predetermined threshold, the system automatically sends replenishment requests to suppliers, ensuring continuous product availability without manual intervention.

Vendor Managed Inventory (VMI)

Retail Link facilitates a Vendor Managed Inventory (VMI) model, where suppliers are responsible for managing their products' inventory at Walmart's warehouses and stores.

This arrangement places the onus on suppliers to keep an optimal stock level, reducing Walmart’s direct involvement in inventory management and enabling more efficient operations.

This collaborative approach between Walmart and its suppliers ensures that shelves are always stocked with the right products at the right time, minimizing stockouts while also keeping inventory levels lean.

Walmart's innovative use of technology in inventory management has been instrumental in sustaining its low-price strategy and market leadership.

Zara: Fast Fashion and Just-In-Time Inventory

Zara, a leading fast fashion retailer, excels in inventory management through its Just-In-Time (JIT) production model.

Just-In-Time inventory management is a strategy aimed at increasing efficiency and decreasing waste by receiving goods only as they are needed in the production process, thereby reducing inventory costs.

This method requires precise planning and a seamless supply chain to avoid stockouts and production delays.

Zara employs JIT through a combination of sophisticated designs, production, and distribution processes. Its approach is characterized by several key components:

Rapid Production Cycles

Zara's design teams work closely with their production facilities to ensure that new fashions can be turned from idea into available product at breakneck speeds.

This proximity between design and production allows for a continuous and efficient flow of goods.

Limited Stock and Frequent Deliveries

Stores receive small quantities of new items twice a week, a practice that not only generates excitement among customers but also reduces the need for large stockrooms.

This strategy keeps inventory levels low and ensures that the production is closely aligned with current demand.

Advanced Data Analytics

Store managers and staff play a crucial role in Zara's JIT strategy by reporting sales data and customer feedback directly to headquarters.

This real-time information influences production decisions, ensuring that popular items are restocked quickly and that underperformers are phased out.

Vertical Integration

Owning much of its production and supply chain enables Zara to maintain a tight grip on its operations, making quick adjustments as needed.

This control is a cornerstone of the JIT strategy, allowing Zara to synchronize its inventory with current fashion trends and consumer demand.

This approach allows Zara to introduce new designs to the market in as little as two weeks, compared to the industry average of six months.

The company maintains minimal stock at its stores and warehouses, thereby reducing overhead costs and minimizing unsold inventory.

Zara's JIT approach not only ensures that the latest fashion trends are readily available to customers but also significantly enhances its supply chain efficiency and sustainability.

Toyota: The Birthplace of Just-In-Time Manufacturing

The JIT inventory management principle, pioneered by Toyota in the 1970s, is an integral part of the Toyota Production System (TPS).

Faced with constrained resources and a competitive market, Toyota sought a lean production system that could respond quickly to changes in demand without the need for extensive inventory holding.

The result was a dramatic shift in how production was organized and managed, leading to the birth of the JIT system.

Toyota's JIT manufacturing is built on several key principles, each designed to optimize production and minimize waste:

Pull System

Unlike traditional manufacturing, which pushes production based on forecasts, JIT uses a pull system triggered by actual demand.

Production starts only when there is a customer order, ensuring that only necessary items are manufactured, thus avoiding overproduction and excess inventory.

Continuous Improvement (Kaizen)

Kaizen, or continuous improvement, is a central element of JIT. Toyota fosters a culture where every employee is involved in suggesting and implementing improvements to the production process.

This relentless pursuit of efficiency and waste reduction is a cornerstone of the JIT methodology.

Takt Time

Takt time is the rate at which products must be made to meet customer demand.

By aligning production speed with takt time, Toyota ensures that each step in the manufacturing process is synchronized to avoid bottlenecks and minimize idle time.

Jidoka (Automation with a Human Touch)

Jidoka is the principle of designing equipment to stop automatically in response to problems.

This allows for immediate intervention to correct issues, preventing defects from being passed down the line and ensuring high-quality production.

Toyota's Just-In-Time manufacturing system is much more than an inventory management strategy; it's a comprehensive philosophy that permeates the company's culture.

Toyota's approach focuses on reducing waste and increasing efficiency by producing and delivering components just in time to be assembled.

Toyota's Kanban system, a key component of JIT, helps manage and control inventory flow, ensuring timely delivery of materials.

Mayo Clinic: Ensuring Availability and Safety

The Mayo Clinic, a world-renowned medical practice and research group, has exemplified excellence not just in patient care but also in operational efficiency, particularly in its inventory management systems.

In the realm of healthcare, inventory management encompasses a wide range of essentials - from medical supplies and drugs to advanced surgical equipment.

The challenges are multifaceted: ensuring availability, maintaining optimal conditions, keeping track of expiration dates, and complying with stringent regulations.

Mayo Clinic's Approach to Inventory Management:

Integration of Cutting-Edge Technologies

Mayo Clinic has been at the forefront of adopting innovative technologies to streamline its inventory management.

Tools such as Radio-Frequency Identification (RFID) tags and Automated Dispensing Cabinets (ADCs) are integral to their system.

RFID tags allow for real-time tracking of inventory items, facilitating automatic reordering when stock levels are low.

Similarly, ADCs enhance medication safety by enabling precise control and tracking of pharmaceuticals, ensuring that the right medication is available at the right time for the right patient.

Data Analytics and Forecasting

The Mayo Clinic leverages data analytics to predict inventory needs accurately.

By analyzing historical usage data, patient admission rates, and even seasonal trends, the clinic can forecast demand for various supplies and medications.

This ensures that they maintain optimal inventory levels - enough to meet patient needs without excessive overstocking, which can lead to waste, especially with items that have limited shelf lives.

Cross-Functional Teams

Effective inventory management at Mayo Clinic is not siloed within individual departments; it's a collaborative effort across various functions.

Cross-functional teams comprising clinicians, supply chain professionals, and administrators work together to evaluate inventory needs, assess supplier performance, and implement improvements.

This collaborative approach ensures that inventory decisions are always aligned with clinical requirements and patient care objectives.

Vendor Partnerships

Maintaining strong relationships with a network of suppliers is crucial for inventory management in healthcare, where supply disruptions can have dire consequences.

The Mayo Clinic invests in building and maintaining robust partnerships with its suppliers, focusing on reliability and quality.

They employ stringent criteria for supplier selection, and in some cases, work collaboratively with suppliers to develop custom solutions that better meet their unique needs.

Conclusion

In the ever-evolving landscape of global business, effective inventory management stands out as a pivotal cornerstone for success across various industries.

The fast-paced world of retail with giants like Walmart and Amazon leveraging advanced data analytics for real-time stock optimization, the impact of well-orchestrated inventory management systems is profound.

Meanwhile, the automotive industry, represented by Toyota, showcases the efficacy of the Just-In-Time (JIT) inventory strategy, minimizing costs and maximizing efficiency.

These real-world examples illuminate the universal importance of adept inventory management - it's not just about keeping the shelves stocked, but doing so in a way that aligns with broader business goals, ensuring agility, sustainability, and competitiveness in today’s market.