Introduction

Understanding and mastering inventory management is pivotal for small businesses looking to drive efficiency and increase profitability.

It serves as the backbone of operations, ensuring that a careful balance is struck between stock availability and the cost of carrying inventory.

Effective management of inventory not only prevents stockouts and avoids excess, which can erode profit margins but can also provide deeper insights into consumer behavior, ultimately allowing for more strategic decision-making.

Consider the case of 'Communitee', a small, emerging fashion retailer in a bustling city neighborhood.

Communitee has carved out a niche for itself by offering unique apparel and accessories sourced from local designers.

Yet, the store's initial unprepared inventory system, which consisted mainly of visual inspections and manual record-keeping, led to frequent stockouts of popular items and overstock of slow-moving products, translating into lost sales and tied-up capital.

Realizing that their current system was not sustainable for growth, the team at Communitee decided to invest time and resources into developing a more robust inventory management strategy.

They adopted a system that offered real-time inventory tracking, allowed for the setting of automated reorder points, and provided valuable reporting tools to assess sales patterns and adjust buying decisions accordingly.

As a result of this shift, Communitee was able to dramatically reduce the instances of stockouts and overstock.

This not only improved customer satisfaction by ensuring popular items were always available but also enhanced cash flow, allowing the store to invest in other areas of the business.

Through the lens of this study case, we shall explore the multifaceted benefits, strategies to adopt, key considerations, and steps for successful implementation, tailored specifically for small businesses to maximize operational efficiency and profitability.

Benefits of Efficient Inventory Management

For small businesses, efficient inventory management offers several tangible benefits:

1. Reduced Costs: Balancing Inventory with Precision

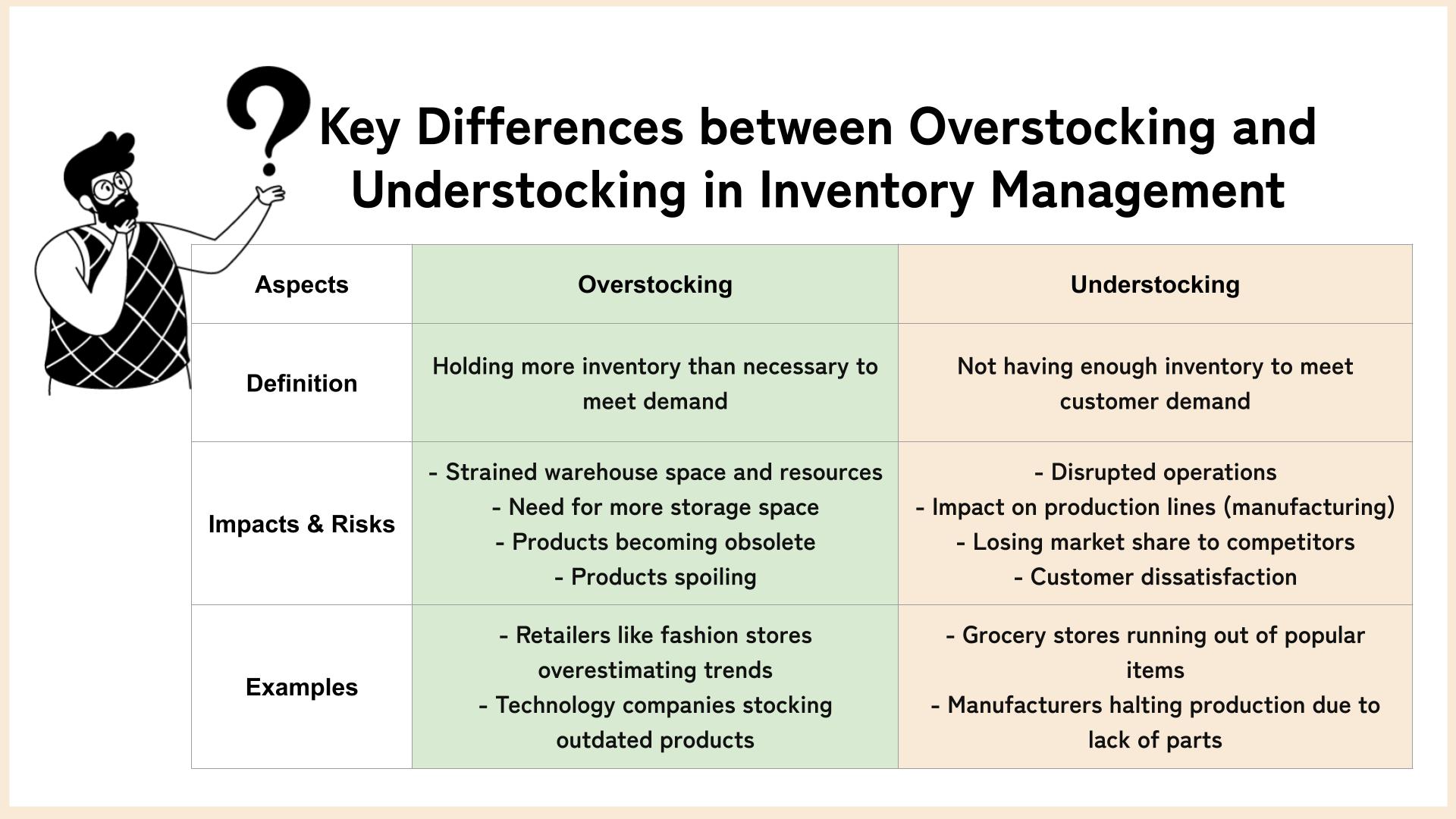

The Issue with Overstocking and Understocking: Overstocking ties up valuable capital in excess inventory, occupying warehouse space and potentially leading to obsolete stock.

Understocking, on the other hand, can result in missed sales opportunities and dissatisfied customers, as products are not available when demanded.

Striking the Perfect Balance: Efficient inventory management helps businesses strike the right balance between too much and too little.

By maintaining optimal inventory levels, businesses can significantly reduce storage costs and minimize the risks associated with dead stock.

It is stated that by addressing the issues of overstocking and understocking, businesses can achieve a significant 10% reduction in inventory costs.

Moreover, it avoids the pitfalls of understocking, ensuring potential sales are not lost due to inventory shortages.

2. Improved Cash Flow: Enhancing Liquidity

The Cash Flow Challenge: Cash tied up in stock is cash not available for other growth opportunities.

For small businesses, where liquidity is often key to flexibility and survival, having too much capital locked in inventory poses a significant financial challenge.

The Inventory Management Solution: By adopting efficient inventory management practices, businesses can improve cash flow management.

This approach ensures that investment in inventory is closely aligned with demand, freeing up cash that can be used for operational expenses or growth initiatives, thereby improving the overall financial health of the business.

3. Enhanced Customer Satisfaction: Fulfilling Demand Reliably

The Customer Expectation: In today's fast-paced market, customers expect quick and reliable fulfillment of their orders.

Failure to meet these expectations can lead to disappointment and drive customers to look elsewhere.

Meeting Expectations with Efficient Inventory: Having the right products available at the right time is pivotal for enhancing customer satisfaction and building loyalty.

Efficient inventory management ensures that popular items are adequately stocked, thus greatly reducing instances of stockouts.

By ensuring products are available when needed, businesses can significantly boost customer satisfaction and foster long-term loyalty.

4. Increased Efficiency: Streamlining Operations

The Burden of Manual Inventory Management: Traditional, manual approaches to inventory management can be time-consuming and error-prone, diverting attention from other critical business areas.

Leveraging Automation for Better Efficiency: A well-implemented inventory management system streamlines processes, from ordering to stock level monitoring and reordering.

Automation reduces the time and effort required to manage inventory, enabling staff to focus on more strategic tasks that add value to the business.

This operational efficiency can lead to significant time and cost savings.

5. Avoidance of Spoilage: Minimizing Losses

The Perishable Problem: For businesses dealing with perishable goods, spoilage is a constant threat that leads to direct losses.

Minimizing Risk through Management: Efficient inventory management can significantly mitigate the risk of spoilage. Systems like First-In, First-Out (FIFO) ensure older stock is sold before newer stock, reducing waste.

By closely monitoring stock levels and shelf life, businesses can adjust orders to match demand, minimizing the risk of unsold perishables and thereby controlling losses.

Strategies for Inventory Management in Small Businesses

Effective inventory management is crucial for the success of small businesses, as it directly impacts their operational efficiency, customer satisfaction, and ultimately, their bottom line.

Implementing smart inventory management strategies can help small business owners avoid common pitfalls such as stockouts, excess inventory, and wasted resources.

This section outlines practical and actionable strategies for small businesses aiming to optimize their inventory management processes.

1. Implement an Inventory Management System

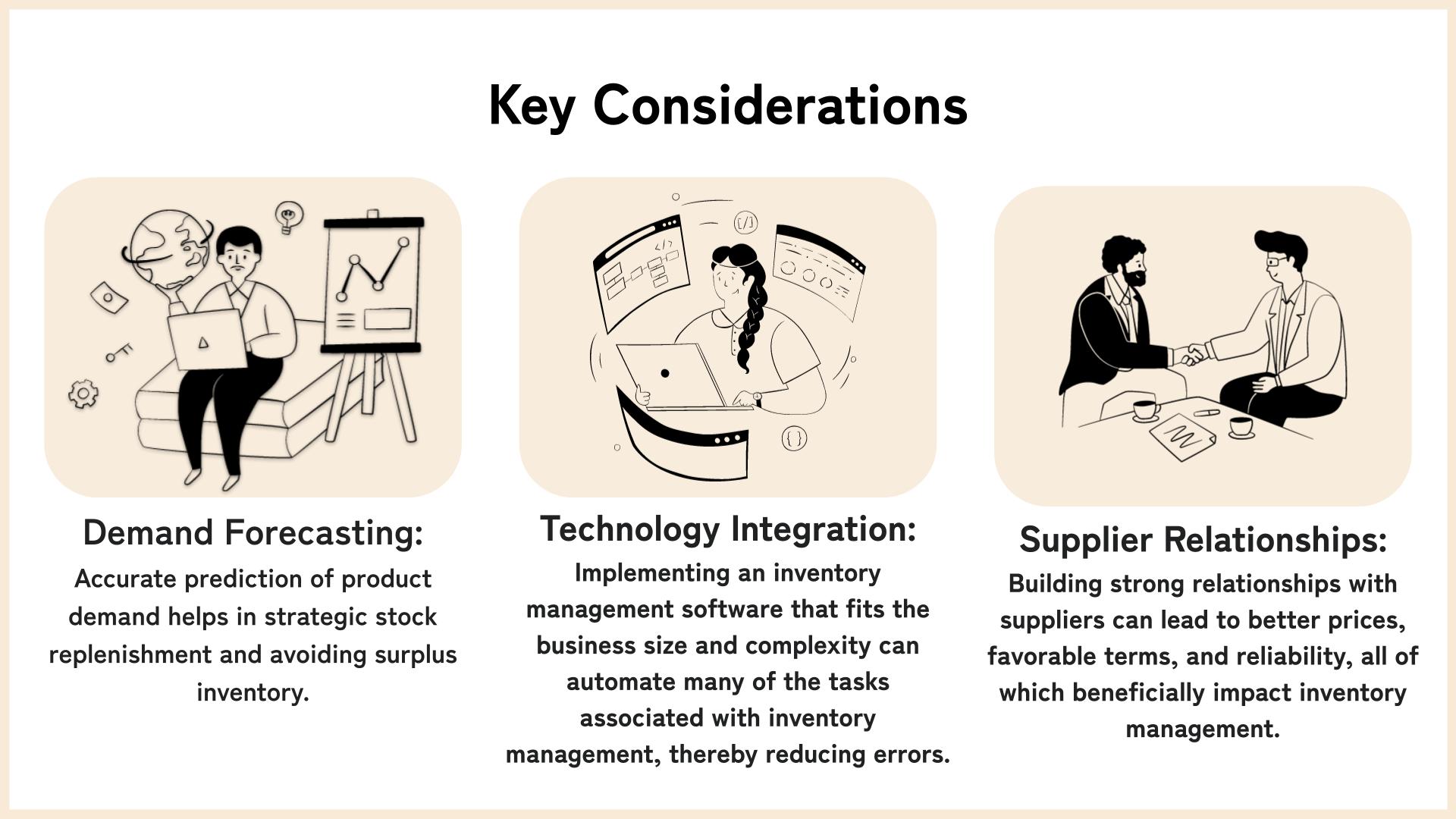

Transitioning from manual tracking methods (like spreadsheets) to a dedicated inventory management system can revolutionize how a small business handles its inventory.

These systems automate tracking, provide real-time inventory levels, and offer insights for better decision-making.

Small businesses should look for systems that integrate with other tools (like accounting software) and can scale with their growth.

Cloud-based options are often more affordable and accessible for small businesses, providing the flexibility to manage inventory from anywhere.

2. Adopt Just-In-Time (JIT) Inventory

Just-In-Time inventory management aims to minimize the amount of inventory on hand by ordering stock close to when it’s actually needed for sale or production.

This strategy can significantly reduce storage costs and minimize the risk of spoilage or obsolescence.

For JIT to be successful, small businesses need dependable suppliers and a clear understanding of their lead times.

Building strong relationships with suppliers ensures that they can accommodate quicker turnaround times, which is critical for the JIT model to work.

3. Conduct Regular Inventory Audits

While an inventory management system automates tracking, regular audits are essential to ensure its accuracy.

Small businesses should conduct periodic physical counts to verify system data, uncover any discrepancies, and adjust records accordingly.

Options include annual full inventory counts, cycle counting (dividing inventory into small portions and counting throughout the year), or using a combination of both, depending on the business size and inventory volume.

4. Analyze and Forecast Inventory Needs

Effective inventory management requires a deep understanding of demand patterns.

Small businesses should analyze sales data to identify trends, seasonal fluctuations, and best-selling items.

This analysis informs smarter purchasing decisions, ensuring stock levels match demand.

Even with accurate forecasts, unexpected spikes in demand can occur. Maintaining a small amount of buffer stock for high-demand items can prevent stockouts without significantly increasing holding costs.

5. Optimize Inventory Layout

The physical organization of inventory can have a significant impact on operational efficiency.

Small businesses should optimize their storage space to ensure fast-moving items are easily accessible and that the warehouse (or storage area) supports efficient picking and packing processes.

The First-In, First-Out (FIFO) principle ensures that the oldest stock is sold first, reducing the risk of spoilage for perishable goods and obsolescence for non-perishables.

This approach requires thoughtful layout planning to facilitate smooth stock rotation.

6. Leverage Dropshipping for Product Expansion

For small businesses looking to expand their product line without significant upfront investment in inventory, dropshipping can be an effective strategy.

In this model, products are shipped directly from the supplier to the customer, meaning the business doesn’t hold the inventory itself.

Successful dropshipping depends on choosing reliable suppliers and maintaining clear communication.

Small businesses should thoroughly vet potential partners to ensure they can meet expectations for product quality and shipping times.

How to Implement Inventory Management in Small Businesses

Step 1: Assess Your Needs

Start by identifying what you want to achieve with your inventory management system.

Common goals include minimizing stockouts, reducing excess inventory, and improving cash flow.

In addition, understand the types of inventory you have (raw materials, works-in-progress, finished goods) and their specific management requirements, such as storage conditions or shelf life.

Understanding these elements helps determine the most suitable inventory system (e.g., perpetual vs. periodic, manual vs. automated).

Step 2: Choose the Right Tools

There are numerous inventory management systems available, ranging from simple spreadsheet templates to sophisticated software solutions.

Select inventory management software that aligns with your business’s needs.

Consider factors like cost, scalability, ease of use, and integration with other systems (like accounting and ERP software).

Many software providers offer free trials. Take advantage of these to test how well different systems meet your needs.

Consider ease of use, as you and your team will be using this system regularly.

Step 3: Set Up Processes

Once you've selected a system, the next step is to input your current inventory. This might be time-consuming but is crucial for accuracy.

Establish clear processes for purchasing, receiving, storing, and selling inventory.

Standard operating procedures (SOPs) ensure consistency and reliability in how inventory is handled.

Step 4: Train Your Team

Your inventory management system will only be as effective as the people using it.

Proper training is essential in helping your staff understand the processes and technologies you are implementing.

Comprehensive training ensures everyone is equipped to manage inventory effectively.

Step 5: Organize Your Inventory

Once you've chosen your software, setting it up correctly is key. This includes:

- Entering Your Current Inventory: Input detailed information about each item, including name, SKU, quantity on hand, reorder point, and cost.

- Organizing Your Inventory: Use categories, tags, and locations to make finding and managing items easier.

- Setting Up Processes: Determine how you will handle purchasing, receiving, picking, and shipping inventory within the system.

Consider implementing organization principles like FIFO (First In, First Out) or LIFO (Last In, First Out) depending on your type of products.

Ensure every item or shelf is clearly labeled. This can help prevent errors in picking and stock counting.

Step 6: Monitor and Adapt

Regularly review performance metrics to measure the effectiveness of your inventory management.

Adapt and improve strategies based on trends, changes in demand, and other relevant factors.

Inventory management is not a one-time setup but a continuous process.

Be prepared to adapt and make changes based on what the data tells you.

Regularly solicit feedback from staff, and look for opportunities to improve efficiency and accuracy.

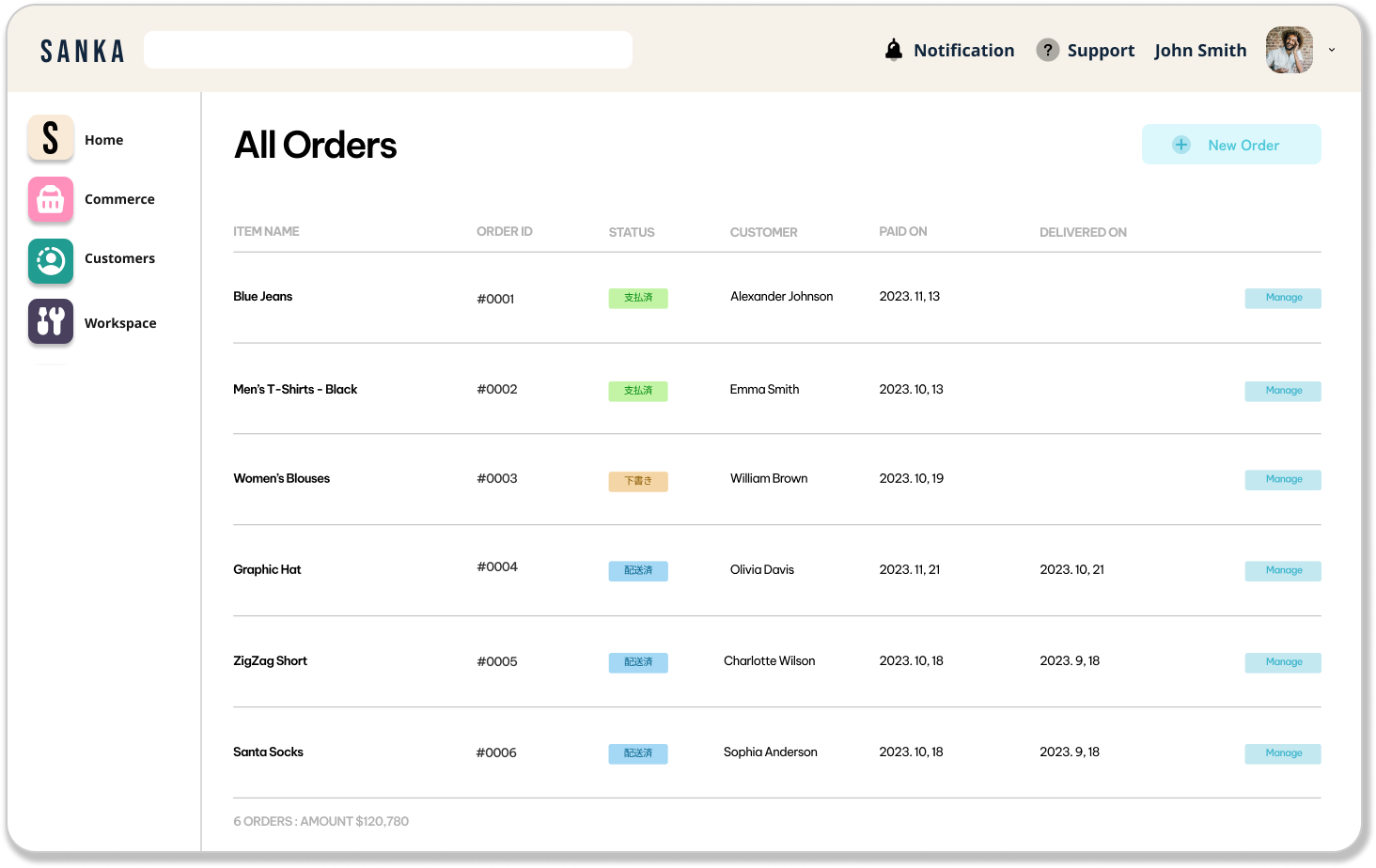

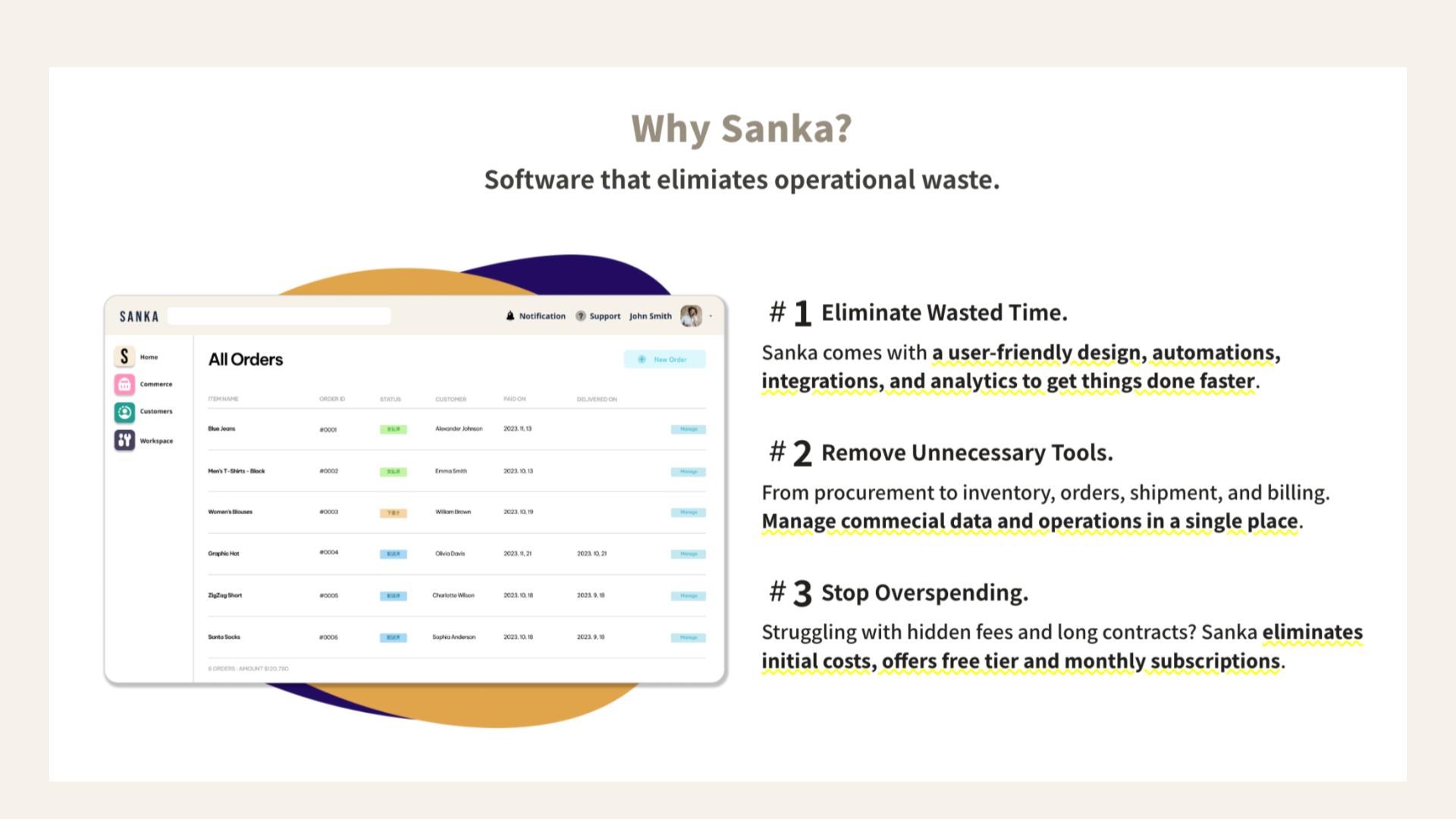

Sanka for Inventory Management

In the evolving landscape of small business operations, the significance of a unified and efficient inventory management system cannot be overstated.

This revelation brings us to a transformative solution that is redefining the efficiency and profitability metrics for small businesses across the globe: Sanka.

Sanka pioneers as a Commerce Management Platform, meticulously designed to streamline the complexity of inventory management, orders and returns, invoices, and purchase orders, among others.

Its service palette is a comprehensive suite that encapsulates the essence of inventory, orders and billing, customer management, and work management—all under a single, user-friendly interface.

This integration not only simplifies operations but also lays down a robust foundation for scaling and optimizing commercial endeavors.

But what sets Sanka apart in the crowded field of inventory management solutions?

Firstly, the platform's commitment to eliminating operational waste stands out prominently.

Sanka is engineered to save invaluable time through automation, analytics, and seamless integrations, leaving behind the cumbersome dependency on manual processes and a jumble of disjointed tools.

By consolidating commercial data and operations, it markedly diminishes the need for multiple tools, ensuring a significant reduction in hidden costs and long contractual obligations.

Furthermore, the power of seamless integration with leading E-commerce and Logistics platforms such as Shopify, Amazon, and others cannot be overstated.

By choosing Sanka, small businesses are not just adopting a software solution; they are embarking on a partnership poised to revolutionize their operational framework.

This is echoed through the testimonials of various industry leaders who have experienced firsthand the transformative impact of Sanka on their operational efficiency and, ultimately, their bottom lines.

Conclusion

For small businesses, mastering inventory management can lead to improved profitability, efficiency, and customer satisfaction.

While the initial setup, including selecting and implementing a suitable system, can be challenging, the long-term benefits far outweigh these upfront efforts.

In the journey towards maximizing efficiency and profitability, small businesses no longer need to navigate the complexities of inventory management alone.

Sanka stands out as a beacon of innovation, simplification, and support, ready to guide businesses towards a future marked by unparalleled operational efficiency.

Embrace Sanka and transform the way your small business thrives in the competitive marketplace.

Explore Sanka today, and unlock the true potential of cohesive commerce management for your business.

By taking a structured approach to inventory management, small businesses can position themselves for sustainable success and growth.