Introduction

Hey there, savvy entrepreneur! If you've stumbled across this post, chances are you're trying to wrap your head around Material Requirements Planning (MRP).

Maybe you've heard it can seriously streamline your production, or perhaps you're just curious about what it could do for your business.

Picture this: You've started a small, vibrant clothing business called "Rising Sun," inspired by the fresh beginnings each sunrise symbolizes.

Each piece of clothing you design carries the warmth and promise of a new day.

As your brand begins to captivate more customers, you find yourself at a crossroads — the demand for your apparel is increasing, and while this is the dream, it also brings a wave of operational challenges.

This is where Material Requirements Planning (MRP) comes into play, not just as a concept, but as the very lifeline that ensured the sun would keep rising for your little shop.

Fear not, because you're about to get a clear, friendly guide to understanding MRP from the ground up. Let’s dive in!

What is Material Requirements Planning (MRP)?

Material Requirements Planning (MRP) might initially sound like just another business acronym, but consider it your GPS in the world of manufacturing.

At its heart, MRP is a system designed to meet three primary goals: ensuring materials are available for production, maintaining the lowest possible material and product levels in stock, and planning manufacturing activities, delivery schedules, and purchasing activities.

Think of it as a clever advisor that helps you figure out what materials you need, how many you need, and when you need them to meet your production schedules effectively.

It's all about having the right stuff, at the right time, in the right quantity. Simple, right?

Flashback to the 1960s, MRP came into existence mainly due to the efforts of one Joseph Orlicky.

He observed the struggles industries faced with inventory control and crafted this system as a solution.

Originally, it was all about helping manufacturers get a grip on their stock, but now, it’s evolved to integrate fully with other business functions, thanks to advancements in technology.

Why is MRP Important?

From small startups to seasoned enterprises, understanding the significance of MRP systems can revolutionize how a company manages its manufacturing processes.

Let's unpack the magic behind Material Requirements Planning (MRP) and dive into why it's not just important, but essential for any budding business ready to take production seriously.

Efficiency is Key

MRP is your organized friend who tells you, “Hey, you need to order more silk now if you want to meet the demand for those scarves next month.”

It is orchestrating every part of your production process so everything runs on time and smoothly.

By telling you what, when, and how much to purchase or produce, MRP keeps your operations humming like a well-oiled machine.

It helps prevent production delays and the awkward situation of having too much or too little stock.

Studies have shown that companies that implement MRP systems can see a reduction in inventory hold costs because they only order what they actually need and reduce wasteful overstock.

Cash Flow Clarity

One of the biggest advantages of implementing an MRP system is the positive impact it has on your cash flow.

With MRP, you're less likely to order more materials than you need, which means less money tied up in unused stock sitting in your warehouse.

Businesses with effective MRP systems in place can improve their inventory accuracy to levels of 98% or higher.

Better inventory accuracy leads to stronger financial stability and less dead stock.

Customer Satisfaction

In the era of instant gratification, customers expect not just quality, but also quick and reliable delivery.

MRP enables businesses to meet these expectations consistently by ensuring that production schedules are closely aligned with customer demand.

When you deliver what your customers want, when they want it, without compromising on quality or timeliness, you build trust and reliability which is the key ingredients for business success.

Risk Mitigation and Flexibility

Unexpected challenges such as supply chain disruptions, sudden spikes in demand, or equipment failures can wreak confusion on unprepared businesses.

MRP provides a bird's-eye view of your operations, supply chain, and inventory levels, empowering you to anticipate issues and adjust plans swiftly.

This level of agility is critical for not just surviving, but thriving in today's dynamic market conditions.

Enabling Scalability

As businesses grow, the complexity of managing production and inventory multiplies.

MRP systems are designed to scale with your business, accommodating increased product lines, more complex manufacturing processes, and a larger customer base.

This scalability ensures that your operations remain efficient and responsive, no matter how large your business grows.

Taking the Leap: Implementing MRP in Your Business

Now that you're acquainted with the basics, implementing MRP might seem like a daunting expedition.

But fear not! Like every hero’s journey, it starts with the first step:

Step 1: Understanding MRP Components

First thing’s first! MRP is all about making sure you have the right materials at the right time for production without overstocking or running short.

This magic happens through a system that helps predict and plan your inventory needs based on your sales forecasts and production schedules.

To navigate the world of MRP, you don't need a map, but you do need to understand a few key elements:

- Bill of Materials (BOM): This is essentially the recipe for your product. For Rising Sun, it's a detailed list of all the materials and components required to create your clothes.

- Master Production Schedule (MPS): This is your timeline showing what products you need to produce, in what quantities, and when they need to be ready. It’s the foundation upon which your MRP system will forecast material requirements.

- Inventory Records: These records are the lifeline of your MRP system, providing up-to-date information on what materials you currently have, what's on order, and what's reserved for future production.

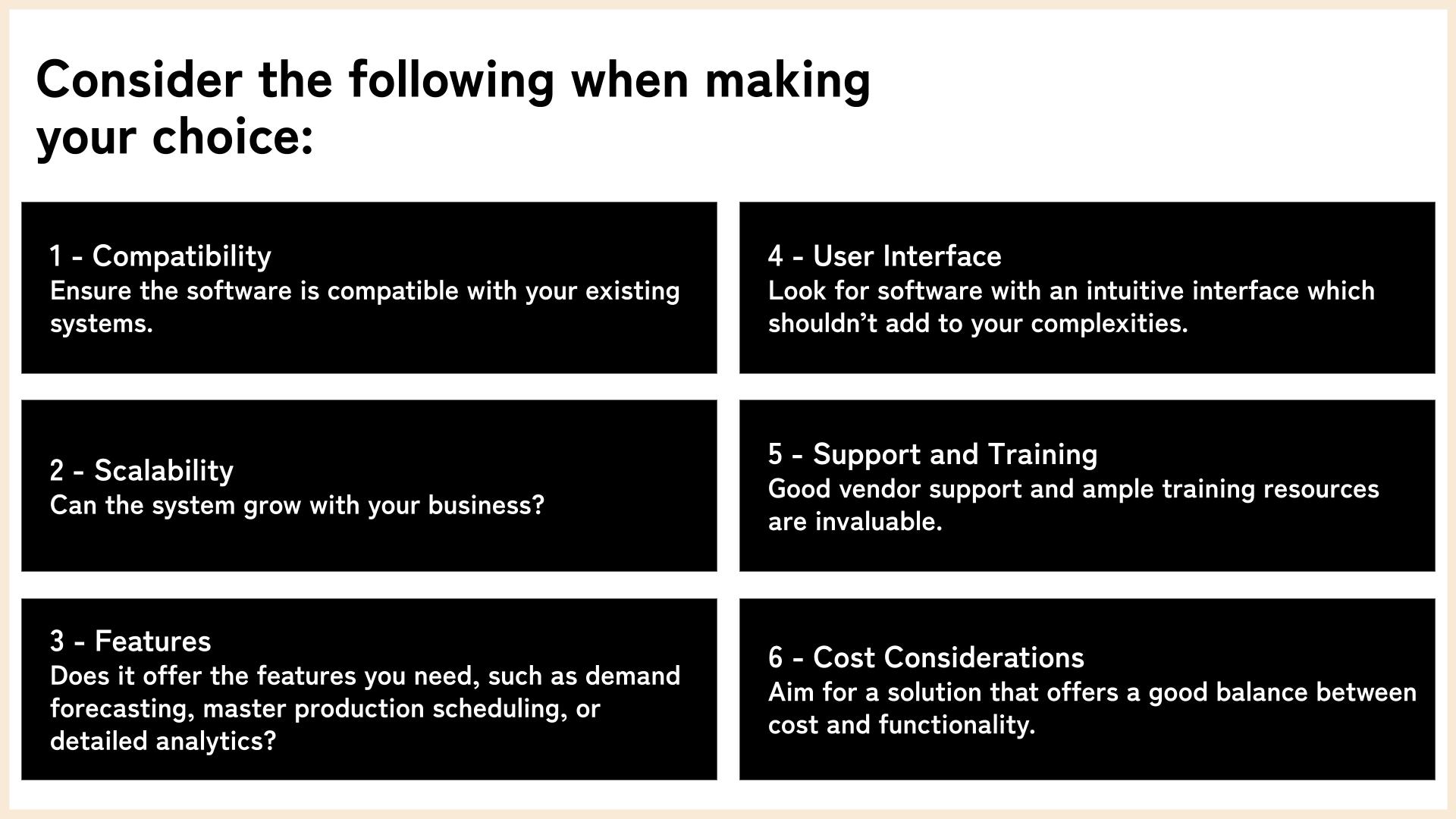

Step 2: Choose the Right MRP Software

Not all MRP systems are created equal. Considering your specific needs is crucial.

For the brand "Rising Sun" for example, the key was finding MRP software that was not just powerful but also intuitive.

Small businesses don't usually have the luxury of large IT departments, so a user-friendly interface was crucial.

Look for a system that integrates seamlessly with your existing processes, is user-friendly, and offers robust support and training.

Think of it as finding a new member for your team who must fit into the existing culture.

Selecting the right MRP software is a strategic decision that can significantly impact the efficiency and success of your operations.

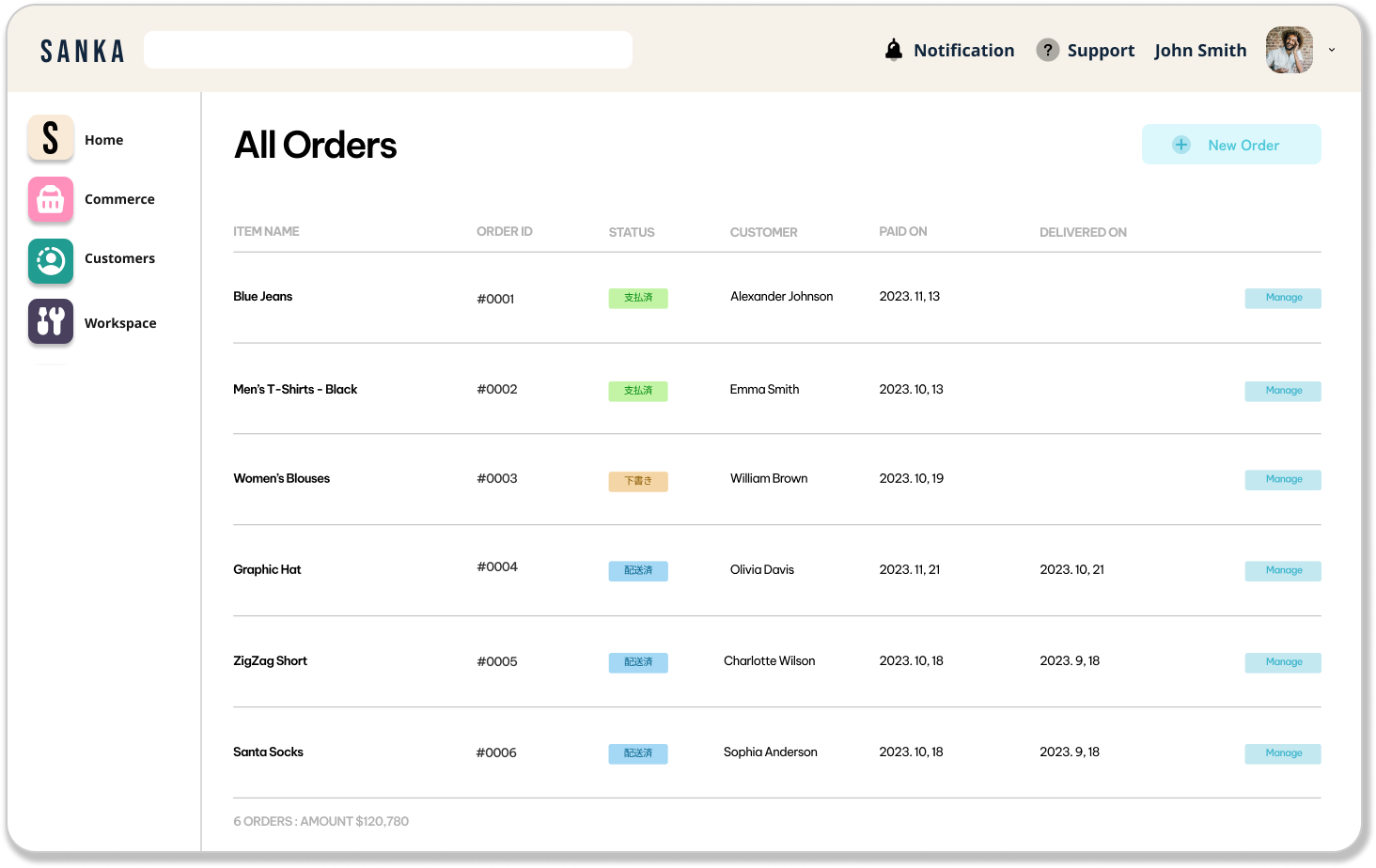

With its comprehensive features, user-friendly design, and robust support system, Sanka stands out as a capable partner in this endeavor.

Sanka offers a comprehensive suite for managing not just your inventory but also purchase orders, orders & shipping, and invoices.

This integrated approach means you have a single source of truth for all your procurement, inventory, and order management needs, eliminating the need for juggling multiple tools.

Ready to explore how Sanka can streamline your material requirements planning? Start your free trial today and experience the benefits firsthand.

Step 3: Clean and Organize Your Data

Before integrating any system, make sure your data is squeaky clean. This includes standardizing how you record inventory levels, supplier information, and production schedules.

Dedicated a few days to ensuring your data was organized—which was a bit like spring cleaning!

It might seem tedious, but clear, accurate data is the cornerstone of effective MRP.

Step 4: Train Your Team

One of the most meaningful steps in your journey was investing time in training your people.

Remember, the magic doesn’t lie solely in the software, but in the people who use it.

Organize training sessions and hands-on workshops to ensure everyone felt comfortable with the new system.

This not only helped in smoothing the initial transition but also empowered the team to make the most out of the system’s features.

You can also held several casual, fun sessions where our team could get hands-on experience with the new system, clearing doubts and building confidence. If the team believes in the tool, half your battle is won.

Step 5: Start with a Pilot Run

It’s wise to start small. Choose a single product line or a particular type of inventory to apply your new MRP system to.

This allows you to see how well the system works and make adjustments without disrupting your entire operation.

Think of this step as the “pilot episode” before you launch the full series.

Step 6: Regular Monitoring and Adjusting

Once your MRP system is up and running, keep an eye on how it’s performing.

Implementing an MRP system isn't a "set-and-forget" solution.

Regular check-ins will help you catch any issues early and also tweak the system for better performance.

Monitor your progress and tweak your parameters (like minimum stock levels and order quantities) to better match your production needs and sales forecasts.

Conclusion

Material Requirements Planning isn’t just software; it’s a comprehensive approach that fine-tunes your production strategy for maximum efficiency, cost-effectiveness, and customer satisfaction.

In a business environment where agility, foresight, and efficiency dictate success, MRP stands out as an indispensable tool.

Whether you're looking to cut costs, satisfy more customers, or simply get a grip on your production schedules, MRP might just be the solution you've been searching for.

Isn't it time you gave your business the edge it deserves?