Introduction

Supply Chain Management (SCM) is the art and science of optimizing the flow of goods and services from their point of origin to the consumer.

It's an invisible force that propels industries forward, ensuring that products are delivered efficiently, costs are minimized, and quality is maintained.

To make the concept of SCM more tangible, let's explore some exemplary instances of supply chain management across various industries, illustrating the diversity and importance of this critical business practice.

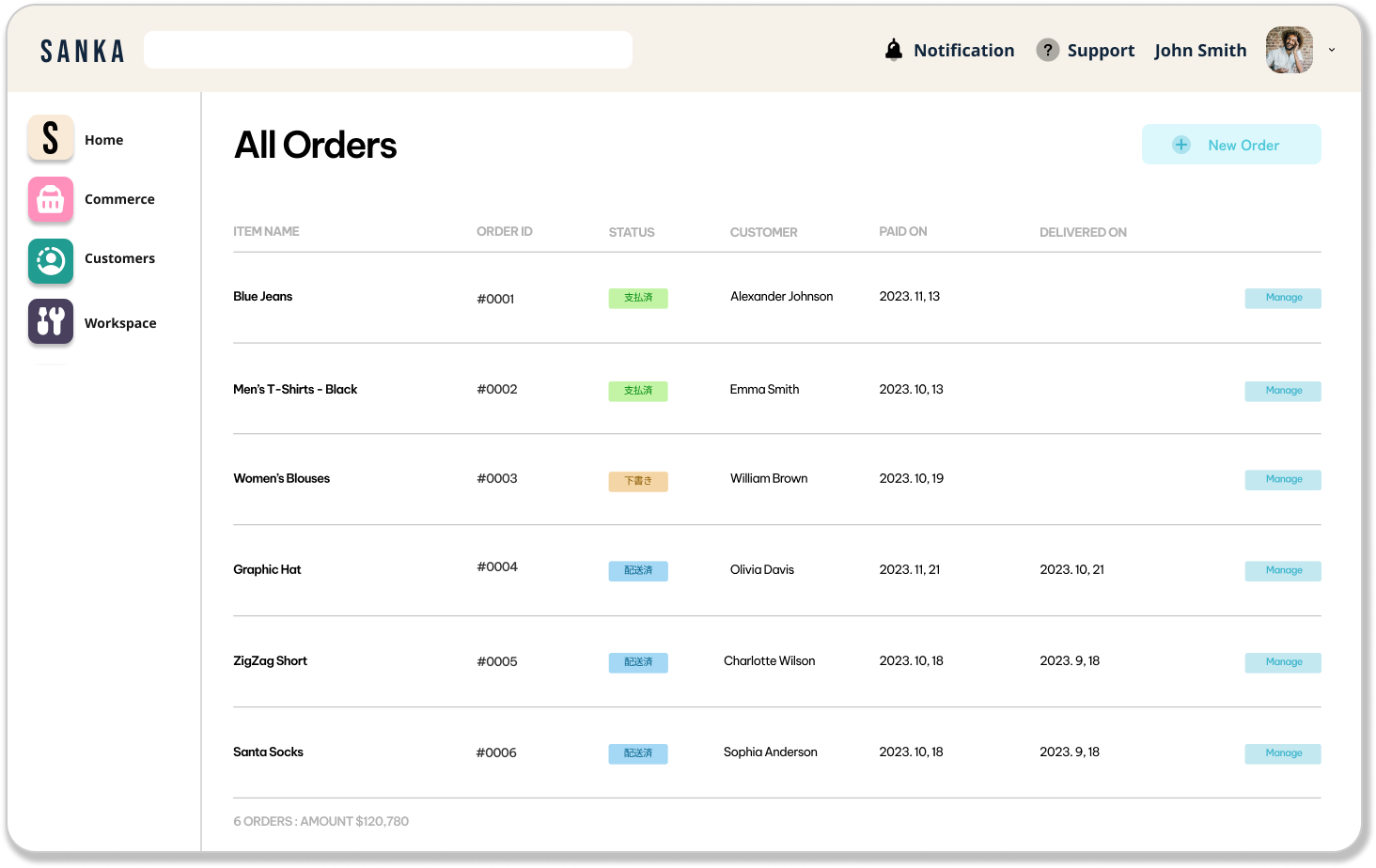

1. Retail: Walmart’s Winning Supply Chain Strategies

Walmart, the world's largest retailer, is renowned for its exceptionally efficient supply chain that leverages technology, strategic vendor partnerships, and a robust distribution network.

Walmart's supply chain is engineered for efficiency, cost reduction, and speed, enabling the behemoth to maintain its promise of offering low prices every day.

Walmart’s adept SCM allows it to offer "Everyday Low Prices" to customers, underpinning its market-leading position.

Key Components of Walmart’s Supply Chain Success

1. Cutting-Edge Technology Integration:

Walmart leverages advanced technology to optimize its supply chain operations.

The use of RFID (Radio Frequency Identification) tags for inventory tracking and sophisticated analytics for demand forecasting are crucial elements.

These technologies enable real-time inventory management, reducing the likelihood of stockouts and ensuring timely product replenishment.

2. Mastery of Cross-Docking:

A vital aspect of Walmart’s SCM strategy is its effective use of cross-docking.

This logistics practice involves transferring products directly from incoming trucks to outgoing trucks, bypassing long-term storage.

Cross-docking minimizes handling costs, reduces storage fees, and shortens delivery times, helping Walmart keep its shelves consistently stocked.

3. Strong Vendor Partnerships:

Walmart has cultivated close relationships with its suppliers, fostering a collaborative approach that benefits both parties.

By integrating technology systems with vendors, Walmart ensures a seamless flow of goods while maintaining high quality standards.

This collaboration results in reduced lead times, lower inventory costs, and improved product availability.

4. Strategic Distribution Centers:

The strategic placement of Walmart’s distribution centers is crucial to its supply chain efficiency.

These centers are located in optimal positions to serve as hubs for Walmart’s logistical operations, ensuring that products are processed and delivered to stores quickly and efficiently.

This extensive network of distribution centers helps minimize transportation costs and delivery times.

5. Data-Driven Demand Forecasting and Inventory Management:

Walmart uses advanced data analytics to predict future product demand with high accuracy.

This data-driven approach allows the company to manage inventory levels effectively, ensuring that stores have the right products at the right time.

Efficient inventory management reduces the risk of overstocking or stockouts, optimizing operational costs and enhancing overall efficiency.

2. Technology: Apple’s Global Supply Network

For businesses aiming to refine their SCM strategies, Apple's example underscores the importance of centralized control, strategic supplier partnerships, sophisticated demand forecasting, and inventory management.

Apple Inc.'s approach to supply chain management highlights a harmonious blend of efficiency, innovation, and strategic foresight.

Let’s break down the core elements of Apple’s SCM strategy, offering a clear blueprint for success.

Key Elements of Apple's Supply Chain Strategy

1. Centralized Decision-Making:

Apple employs a centralized decision-making model, where a dedicated team oversees crucial aspects of the supply chain, including inventory management, supplier selection, and distribution.

This centralized approach ensures consistency in strategy execution, allowing Apple to maintain strict control over quality, costs, and delivery schedules.

2. Rigorous Supplier Selection and Management:

Apple’s commitment to high-quality products is reflected in its careful selection of suppliers.

By choosing partners that meet stringent quality and ethical standards, Apple minimizes supply chain disruptions and maintains product excellence.

The company also invests in supplier relationships through training and capacity-building programs, ensuring a responsive and resilient supply network.

3. Advanced Demand Forecasting:

Utilizing sophisticated analytics, Apple accurately predicts product demand, which is critical for managing inventory and launching new products.

This precise forecasting allows Apple to optimize inventory levels, ensuring products are available when needed while avoiding overstocking or shortages.

4. Lean Inventory Management:

Apple’s lean inventory strategy focuses on minimizing stock levels of components and finished goods.

By frequently depleting inventory, Apple reduces storage costs and mitigates risks associated with holding large quantities of stock.

This approach, combined with robust demand forecasting, enables Apple to remain agile and responsive to market changes.

5. Supply Chain Diversification:

To mitigate risks, Apple has increasingly diversified its supply chain, expanding its supplier base and manufacturing operations across different regions.

This strategy enhances Apple's resilience against geopolitical issues, trade disputes, and regional disruptions, ensuring a robust and flexible supply chain capable of withstanding external challenges.

3. Automotive: Toyota’s Just-In-Time (JIT) Production

Toyota Motor Corporation’s implementation of the Just-In-Time inventory system revolutionized automotive manufacturing and SCM as a whole.

JIT minimizes inventory levels, reducing holding costs and capital tied up in stock. Toyota’s supply chain is designed to deliver parts to factories exactly when they're needed - not a moment sooner or later.

This strategy, central to the Toyota Production System (TPS), is not only a cornerstone of the company's manufacturing prowess but also a model of efficiency and agility in supply chain management.

Key Elements of Toyota’s JIT Production

1. Eliminating Waste:

The JIT principle hinges on producing only what is needed, when it is needed, and in the exact amount needed. By doing so, Toyota minimizes waste – whether it's in terms of materials, inventory, or labor.

This lean approach ensures resources are utilized efficiently, significantly reducing costs and enhancing productivity.

2. Continuous Improvement (Kaizen):

Integral to JIT is the concept of 'Kaizen', or continuous improvement. At Toyota, every employee, from the assembly line workers to the executives, is encouraged to suggest ways to improve efficiencies.

This culture of constant refinement helps Toyota maintain a competitive edge, keeping the production process as efficient and up-to-date as possible.

3. Strong Supplier Relationships:

A key component of Toyota’s JIT strategy is its close and collaborative relationships with suppliers. Toyota shares information freely with its suppliers and involves them in the planning process.

This integration allows for synchronized production schedules, meaning suppliers deliver parts and materials 'just in time' for assembly.

This eliminates the need for large stockpiles of inventory, reducing storage and holding costs.

4. Takt Time:

Toyota carefully calibrates its production speed (takt time) to align with customer demand.

Takt time is the rate at which a completed product is finished to meet customer demands.

By adjusting production rates, Toyota ensures that it is building cars efficiently and without surplus.

5. Flexibility:

A versatile production system is vital for JIT to succeed. Toyota's manufacturing processes and workforce are designed to be flexible, allowing them to quickly adapt to changes in production type or volume.

This adaptability is crucial for managing fluctuations in demand and avoiding bottlenecks.

4. Fast Food: McDonald’s Farm to Fork

In an era where consumers are ever more concerned about where their food comes from, McDonald’s, the global fast-food behemoth, answers with its transparent and sustainable "Farm to Fork" strategy.

McDonald's supply chain is a complex network that includes suppliers, logistics partners, and distribution centers, all orchestrated to deliver fresh and safe ingredients.

Farm to Fork is McDonald’s initiative to ensure transparency, sustainability, and efficiency across its entire supply chain.

From the sourcing of raw materials to the preparation and service of meals in restaurants, every step is carefully managed to adhere to high standards of quality and environmental stewardship.

This strategy emphasizes direct connections with farmers, sustainable agricultural practices, and ensuring the ethical treatment of animals.

Key Components of McDonald’s Farm to Fork Strategy

1. Sourcing with Integrity:

McDonald’s places great emphasis on understanding where their ingredients come from and ensuring they are sourced ethically and sustainably.

Relationships with suppliers are built on mutual trust and shared values, where suppliers are vetted to adhere to McDonald’s high standards for quality, safety, and sustainability.

2. Transparency and Traceability:

Through its Farm to Fork strategy, McDonald’s strives for complete transparency in its supply chain.

This means having a system in place to trace the origin of all ingredients used in their restaurants.

Such transparency reassures customers about the quality and safety of the food they are consuming.

3. Focus on Sustainability:

From reducing greenhouse gas emissions to sustainable packaging, McDonald’s commitment to sustainability is integral to its Farm to Fork strategy.

By working closely with farmers, the company promotes agricultural practices that preserve natural resources and minimizes environmental impact.

4. Quality Control:

Quality is non-negotiable within the Farm to Fork supply chain. This involves strict standards and regular audits of suppliers to ensure that only the highest quality ingredients are used.

McDonald’s invests in training and support for its suppliers to meet these requirements consistently.

5. Engaging with Local Communities:

Where possible, McDonald’s prioritizes sourcing from local suppliers to support communities and reduce transportation emissions.

This not only contributes to local economies but also ensures the freshness of ingredients.

5. E-Commerce: Amazon’s Innovation-Driven Supply Chain

In the rapidly evolving landscape of e-commerce, Amazon stands as a towering example of how continuous innovation within supply chain management can yield unprecedented success.

With a business model heavily reliant on the efficiency and reliability of its logistical operations, Amazon's supply chain strategy is a critical component of its business.

Their constant innovation in SCM, like drone delivery experiments, ensures Amazon remains at the forefront of retail logistics, delivering impressive customer service.

Understanding Amazon’s approach offers valuable insights for businesses looking to refine their e-commerce strategies in an increasingly digital marketplace.

Key Elements of Amazon’s Supply Chain Innovation

1. Advanced Warehouse Technology:

Amazon utilizes state-of-the-art automation and robotics in its fulfillment centers to streamline the sorting, packing, and shipping process.

Technologies such as the Kiva Robots (now Amazon Robotics) significantly reduce the time and manpower required to process orders, enabling rapid delivery times.

2. Optimized Inventory Management:

Through sophisticated algorithms and machine learning, Amazon predicts purchasing trends and optimizes its inventory accordingly.

This predictive approach to inventory enables Amazon to pre-position goods closer to potential buyers before they’re even ordered, dramatically reducing shipping times and costs.

3. Global Logistics Network:

Amazon has built a vast network of fulfillment centers, sortation centers, and delivery stations worldwide.

This extensive infrastructure allows Amazon to quickly move goods to areas where they are in high demand, making their supply chain extremely reactive to customer needs.

4. Customer-Centric Return Policy:

Amazon’s easy and efficient return policy is an integral part of its supply chain strategy, designed to enhance customer satisfaction and loyalty.

By making returns hassle-free, Amazon ensures a positive post-purchase experience, which is crucial in the competitive e-commerce space.

5. Last-Mile Delivery Innovations:

Amazon has been pioneering in the area of last-mile delivery – the final step of the delivery process where goods are moved from a transportation hub to the final delivery destination.

From Amazon Prime Air (drone delivery) to Amazon Flex (crowdsourced delivery network), these innovations are tailored to reduce delivery times and increase efficiency.

6. Pharmaceuticals: Pfizer’s Cold Chain Logistics

Pfizer, a leading pharmaceutical company, exemplifies excellence in supply chain management with its cold chain logistics capabilities, essential for transporting temperature-sensitive products like vaccines.

Cold chain logistics refers to the process of transporting and storing products at specific temperatures from the point of manufacture to the end consumer.

For pharmaceuticals, maintaining the correct temperature is vital to preserving the efficacy and safety of medicines, especially vaccines like those developed for COVID-19.

During the COVID-19 pandemic, Pfizer’s SCM ensured the delivery of its vaccine globally, illustrating the critical role of supply chain management in public health.

This aspect of supply chain management is crucial not only for Pfizer’s operational success but also for ensuring that life-saving medications reach patients in optimal condition across the globe.

Key Elements of Pfizer’s Cold Chain Strategy

1. Advanced Packaging Solutions:

Pfizer uses specially designed thermal packaging that can maintain temperatures for extended periods.

For example, the COVID-19 vaccine developed by Pfizer requires storage at approximately -70 degrees Celsius.

The company developed custom thermal shippers using dry ice to keep this temperature stable for up to 10 days unopened.

2. Strategic Distribution Partnerships:

Understanding that a reliable distribution network is key, Pfizer collaborates with experienced logistics partners who specialize in handling sensitive pharmaceuticals.

These partnerships ensure a seamless flow of products from manufacture to delivery points worldwide.

3. Real-time Temperature Monitoring:

Throughout the transportation process, Pfizer employs advanced GPS-enabled technologies to monitor the temperature of their shipments in real time.

This immediate data allows Pfizer to react quickly if any deviations occur, thus safeguarding the shipment’s integrity.

4. Robust Contingency Planning:

Given the risks associated with transporting sensitive products, Pfizer has developed comprehensive risk management procedures and contingency plans.

These plans are designed to handle potential disruptions like extreme weather conditions, transportation delays, or technical failures.

7. Fashion: ZARA’s Exceptional Supply Chain Management Strategy

In the world of fast fashion, ZARA, a flagship brand of the Spanish retail giant Inditex, stands out for its distinctive supply chain management strategy.

ZARA's approach has not only revolutionized the fashion industry but also provided a blueprint for retail success.

ZARA's supply chain management is distinguished by its agility, efficiency, and customer-centric focus.

The brand's strategy revolves around the concept of "fast fashion," where the goal is to reduce the time it takes to move designs from the drawing board to the store shelves.

Key components of ZARA’s SCM Strategy

1. Vertical Integration:

ZARA maintains considerable control over its supply chain through vertical integration.

This means that ZARA owns several tiers of its supply process, including manufacturing, logistics, and distribution.

This level of control allows for rapid response to the latest fashion trends and customer demands.

2. Localized Production:

Unlike competitors who outsource production to low-cost regions, ZARA keeps a significant portion of its production in Spain and nearby countries.

This geographical proximity enhances flexibility and speed in the manufacturing process, enabling ZARA to introduce new products in just a few weeks.

3. Small Batch Production:

ZARA produces its garments in small batches. This approach minimizes the risk of overproduction and allows the company to test new designs in the market without significant investment.

If a particular style receives a favorable response, ZARA quickly ramps up production to meet demand.

4. Advanced Inventory Management:

ZARA employs sophisticated inventory management systems to minimize stock levels and avoid overstock.

The company replenishes its stores twice a week with new items, keeping the inventory fresh and aligned with current fashion trends.

This also encourages frequent visits by customers eager to discover new products.

5. Strategic Store Placement and Design:

ZARA places great emphasis on the location and layout of its stores. The company invests in prime retail spaces and designs its stores to enhance the customer experience.

This strategic placement and design contribute to ZARA’s strong brand presence and market penetration.

Conclusion

These examples from various industries highlight the versatility and importance of supply chain management in today’s global economy.

Whether it’s delivering everyday low prices, launching innovative products, ensuring food quality, expediting online orders, or saving lives with medicines, SCM is at the heart of business success.

For companies looking to thrive in their respective markets, investing in, innovating, and optimizing their supply chain operations is not just advisable; it's imperative.