Introduction

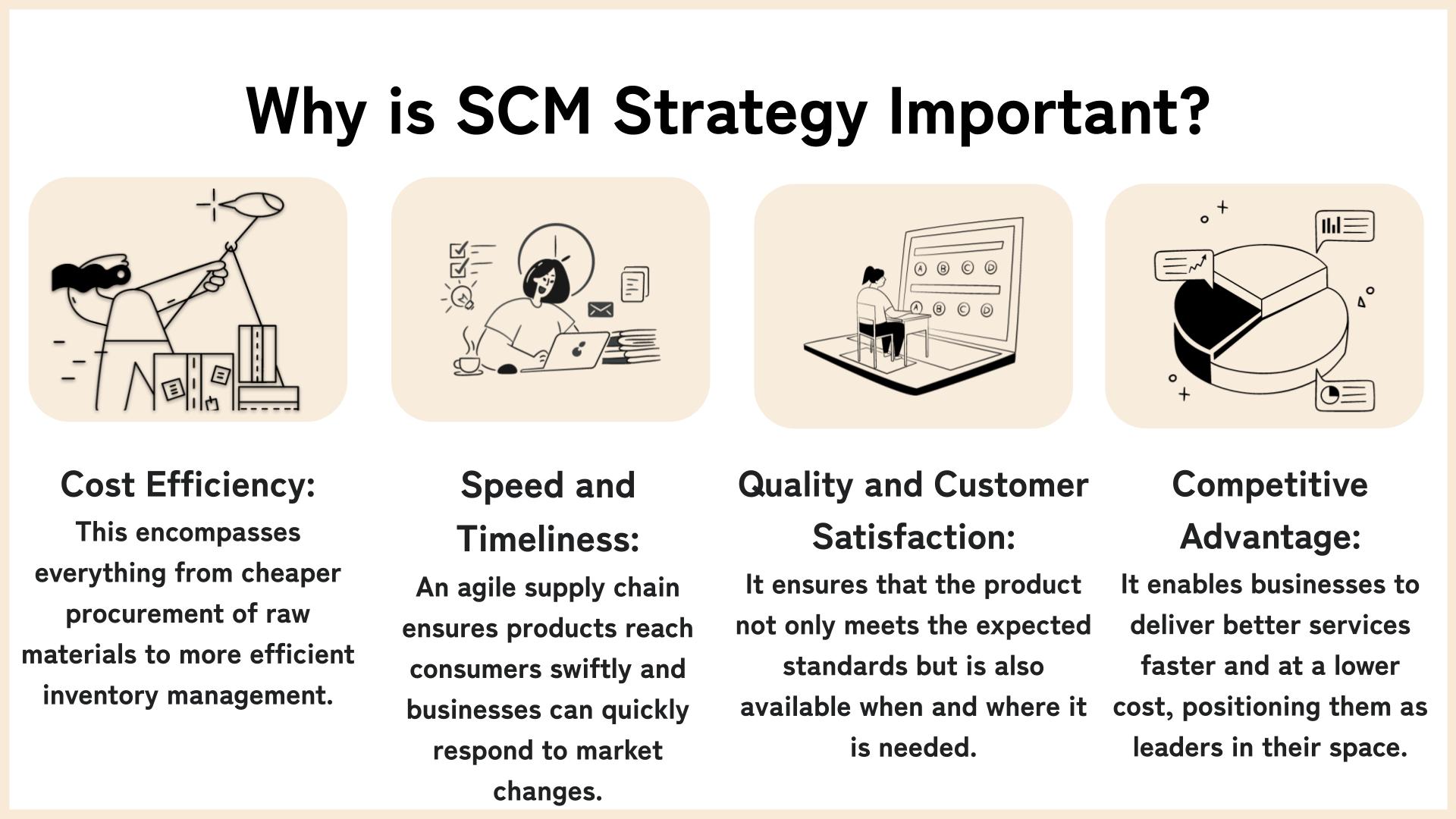

Supply Chain Management is essentially the backbone of any business, ensuring the smooth flow of goods and services from suppliers to customers.

It encompasses everything from procuring raw materials to delivering the final product to the consumer's doorstep.

An optimal SCM strategy can lead to reduced costs, increased efficiency, and superior customer satisfaction—key ingredients for business success.

Procurement Tactics stated that based on The GEODIS Supply Chain Worldwide Survey, which involved 623 industry professionals across 17 countries, revealed that supply chain visibility ranks as the third most critical strategic priority today.

But how does one go about crafting and implementing such a strategy?

To help you navigate through these questions, we will delve into the fundamental principles of supply chain management strategy and uncover how embracing these strategies could be the game-changer for your business growth.

What is Supply Chain Management Strategy?

At its core, a Supply Chain Management (SCM) Strategy is a carefully constructed plan that a company uses to ensure the most efficient and effective movements of goods and services from start to finish.

Think of Supply Chain Management Strategy as the master plan that manages the flow of products and services from the raw materials stage all the way to the customer.

Much like a road trip requires a map, an SCM strategy guides every step of the journey, ensuring that everything runs smoothly, efficiently, and to the satisfaction of all parties involved.

To better understand SCM strategy, imagine the journey of a simple coffee cup.

The raw materials like ceramic, paint, and packaging need to be sourced from different suppliers.

These materials are then transformed into the coffee cup at a manufacturing site.

Finally, the cup makes its way through various distribution channels until it reaches the coffee lover’s shelf. An effective SCM strategy ensures that each of these steps is executed in the most optimal way.

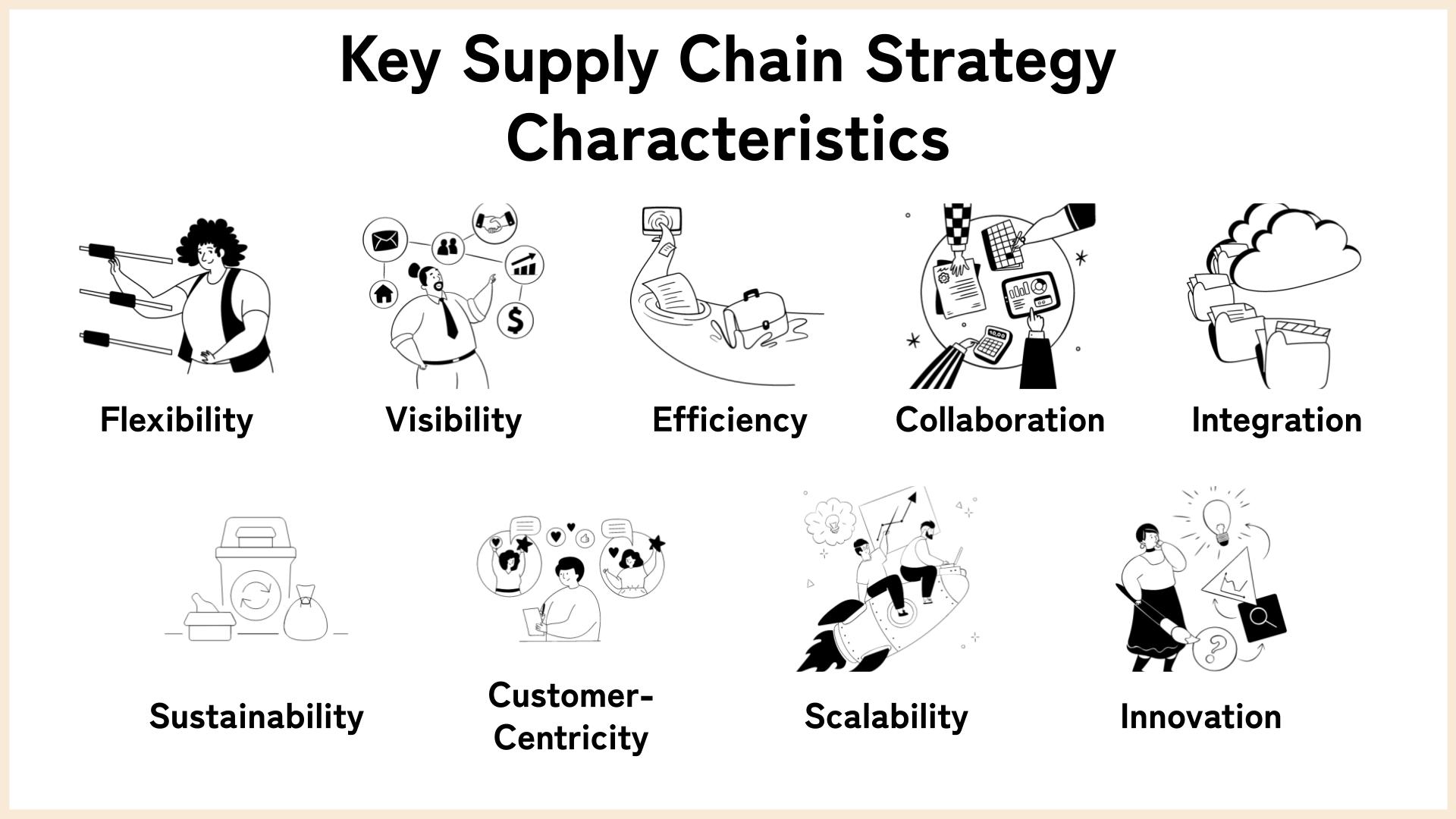

Key Supply Chain Strategy Characteristics

Understanding what makes a supply chain strategy not only functional but outstanding is critical for businesses.

Here's a deep dive into the key characteristics that separate a top-notch supply chain management strategy from an average one:

Flexibility

A highly effective supply chain strategy must be flexible, able to adapt to the inevitable changes that occur in the marketplace.

Whether it's a sudden change in consumer demand, a new trend, or unexpected disruptions like natural disasters or global events, a flexible strategy can pivot quickly to minimize negative impacts and seize new opportunities.

Visibility

Visibility within a supply chain means having clear insight into every aspect of the process at any given moment.

This includes understanding inventory levels, the status of shipments, and production schedules in real-time.

High visibility allows businesses to make informed decisions quickly, reducing the risks of excess inventory, stockouts, and other inefficiencies.

Efficiency

Efficiency in supply chain strategy is about optimizing processes to achieve the maximum output for the least input.

This doesn't just mean cutting costs; it's about streamlining operations, reducing waste, and improving the speed and quality of delivery to the customer.

Collaboration

A successful supply chain strategy involves collaboration among all stakeholders, including suppliers, manufacturers, distributors, and retailers.

Open communication and sharing of information lead to better synchronization, reducing bottlenecks and smoothing out the entire process from procurement of raw materials to the delivery of finished products.

Integration

Seamlessly integrating the various components of the supply chain is crucial.

Today's sophisticated supply chain management software can connect procurement, manufacturing, distribution, and retailing into one cohesive unit.

Such integration ensures that all parts of the chain are informed by the same data set, reducing errors and aligning goals.

Sustainability

An increasingly important characteristic of a supply chain strategy is sustainability.

This involves managing environmental, social, and economic impacts within the supply chain.

Consumers and regulators alike demand environmentally friendly and ethically sourced products, making sustainability a key feature of a modern supply chain.

Customer-Centricity

At the end of the day, a supply chain strategy exists to serve the customer.

As such, a truly outstanding SCM strategy must be customer-centric. It should strive to meet consumer demands for quality, speed, and convenience.

This includes personalization of products and services, flexible delivery options, and an easy return policy.

Scalability

Businesses grow and change size over time, and a supply chain strategy should be designed to scale up or down as necessary.

Scalability helps businesses respond to growth opportunities or contraction without extensive overhauls of their supply chain.

Innovation

Lastly, a key characteristic of a great supply chain strategy is a commitment to innovation.

This could mean adopting new technologies like blockchain for better security and transparency or exploring new business models that better serve the changing marketplace.

Continuous improvement helps businesses stay ahead in a competitive environment.

6 Types of Supply Chain Strategies

Supply chain strategies are essentially the blueprints that guide the flow of goods and services from supplier to customer.

The right strategy can help companies reduce costs, improve efficiency, and enhance customer satisfaction.

Let’s explore six fundamental types of supply chain strategies that businesses can leverage to stay ahead in the competitive market.

1. Lean Strategy

As the name suggests, a Lean supply chain strategy is all about trimming the fat off your operations.

It focuses on eliminating waste within the supply chain—be it excess inventory, extended wait times, or unnecessary steps in the production process.

The objective is to create a more efficient, cost-effective system that delivers value by optimizing resources and maximizing productivity.

2. Agile Strategy

In a world where market conditions and consumer preferences change at the drop of a hat, an Agile supply chain strategy is your best bet to stay flexible.

This approach allows companies to quickly adapt to changes by having responsive systems in place.

It prioritizes the ability to reconfigure the supply chain and adjust production volumes to meet varying demand levels.

An agile strategy is often adopted by businesses operating in volatile markets.

3. Speculation Strategy

Speculative supply chain strategies are based on predicting future market trends and consumer demands.

Companies embracing this strategy often purchase and store large quantities of product based on their market forecasts.

While this can lead to savings if demand is accurately predicted, there's the inherent risk of overstocking should predictions not align with actual consumer behavior.

This strategy requires robust market analysis and risk management.

4. Hybrid Strategy

Hybrid strategies combine elements of both Lean and Agile approaches to offer the best of both worlds.

Organizations using a hybrid supply chain strategy aim to be cost-effective through lean processes while also retaining enough flexibility to adapt to market changes.

For instance, they might employ Lean practices in predictable markets or with steady product lines, and Agile strategies for new product launches or in less predictable environments.

5. Responsive Strategy

Responsive supply chain strategies prioritize the ability to respond promptly to the market and customer demands.

This includes shortening lead times and being able to ramp up (or down) production quickly.

Being responsive requires a deep understanding of customer needs, robust forecasting systems, and agile operations that enable businesses to act swiftly.

It’s ideal for companies in fast-paced industries where trends and customer preferences fluctuate frequently.

6. Customization Strategy

A supply chain strategy centered on customization aims to provide customers with tailored products and services.

This often means postponing the final assembly or customization of a product until the last possible moment (also known as postponement).

This strategy allows for a high degree of personalization while keeping inventory costs down and making production more streamlined.

Companies in industries where personalization is a key differentiator often employ a customization strategy.

Tips for Optimal Supply Chain Management Strategies

Navigating the intricacies of supply chain management can be daunting for anyone, from new entrants to seasoned professionals.

To steer you in the right direction, here are some practical tips for optimizing your supply chain management strategies.

1. Embrace Technology

The use of technology can significantly enhance the efficiency and responsiveness of your supply chain.

Companies utilizing advanced supply chain technologies, like AI and machine learning, see a 15% reduction in logistics costs.

Consider investing in Supply Chain Management (SCM) software that integrates aspects like inventory management, order processing, and transportation logistics.

Also, explore the implementation of technologies such as IoT (Internet of Things) for real-time tracking of shipments and RFID (Radio Frequency Identification) for instant inventory updates.

2. Foster Strong Supplier Relationships

A supply chain is only as strong as its weakest link. Building robust relationships with your suppliers can lead to better pricing, priority service, and more cooperative problem-solving when issues arise.

Regularly communicate with your suppliers, understand their capabilities and constraints, and create a mutually beneficial environment.

3. Streamline Operations

Assess each step of your supply chain to identify areas that can be streamlined for improved efficiency.

Minimize the number of touches or handoffs each product requires as it moves through the supply chain.

This can reduce the risk of errors, cut down on delays and, ultimately, lower costs.

4. Implement an Effective Inventory Management System

Too much inventory can lead to excess costs, while too little can result in stockouts and lost sales.

Implementing an effective inventory management system will help ensure that you have the right products, in the right quantities, at the right time.

This may involve techniques like Just-In-Time (JIT) inventory, which aims to receive goods only as they’re needed in the production process, thus minimizing inventory costs.

5. Prioritize Forecasting Accuracy

Accurate demand forecasting can help you better prepare for fluctuations in the market, reducing the risk of overproduction or stockouts.

Utilize historical sales data, market trends, and predictive analytics to make informed forecasts. This will assist in planning for future production and inventory needs.

6. Develop Flexible Supply Chains

In today’s volatile market landscape, flexibility and adaptability are key traits of a successful supply chain.

Businesses should be ready to pivot in response to disruptions or changes in demand.

Having contingency plans, alternative suppliers, and flexible transportation options can help navigate unexpected challenges.

7. Focus on Quality Control

Implement quality control measures at various stages of the supply chain to mitigate the risk of defective products reaching the customer.

This may mean stricter evaluations of suppliers’ quality systems or more frequent inspections during production.

By ensuring product quality, you reduce the costs associated with returns and enhance your brand’s reputation.

8. Continual Improvement

The supply chain industry is ever-evolving, and so should your strategies.

Adopt a philosophy of continuous improvement where you regularly evaluate and refine your supply chain processes.

Encourage feedback from employees, suppliers, and customers to identify improvement opportunities.

9. Train Your Team

Your supply chain management team is pivotal to implementing and maintaining your strategies.

Invest in their professional development through training and certifications to ensure they are equipped with the latest knowledge and skills in SCM best practices.

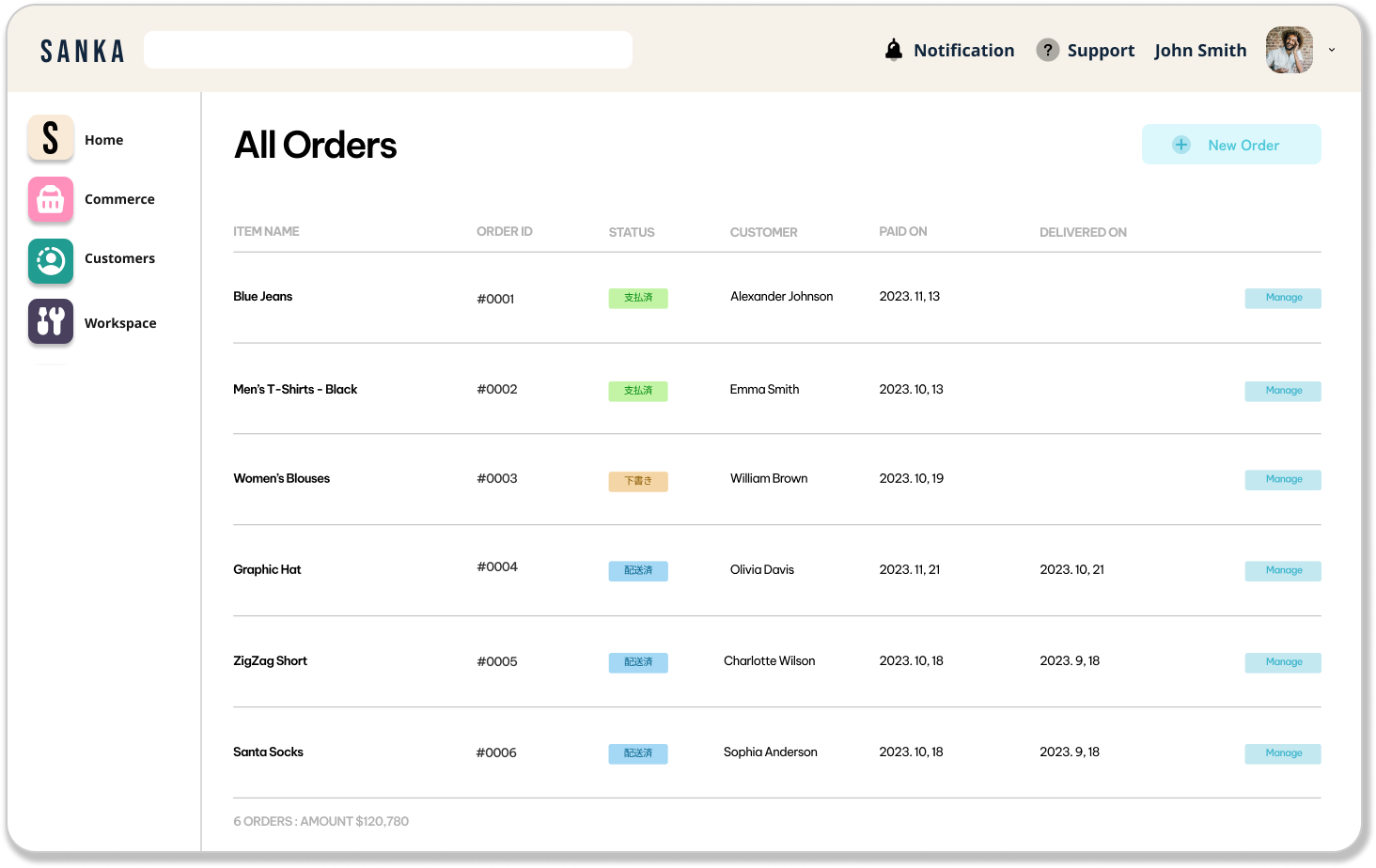

Ready to elevate your business efficiency and bid farewell to the cumbersome spreadsheets?

It's time to decode the ultimate strategy for supply chain success! Discover how Sanka transforms the complexity of supply chain management into a seamless, streamlined process.

Sanka is not just a platform; it's your strategic partner in managing your business operations effortlessly.

With Sanka, you can bring all your operational elements into one user-friendly hub, breaking down silos and fostering a cohesive approach to supply chain management.

Don't let traditional methods hold back your business potential.

Unlock Your Business's Full Potential with Sanka Today!

Conclusion

The right Supply Chain Management Strategy is a game-changer, transforming the complex jigsaw of logistics, procurement, and customer service into a holistic, efficient, and customer-focused enterprise.

For businesses choosing to pave the way in operational excellence, investing time and resources in developing a robust SCM strategy is not just wise—it's essential.

Remember, at the heart of a great strategy is the constant pursuit of efficiency, resilience, and above all, meeting the needs of the dynamic market and its consumers.