Introduction

Hey there, business enthusiasts! Are you feeling a bit overwhelmed by the idea of managing a warehouse?

Not sure where to start or how to make sense of all the jargon floating around? Well, you're in luck!

Today, we're breaking down the basics of Warehouse Management Systems (WMS) in a way that's easy to grasp and free from mind-boggling technicalities.

So, grab a cup of your favorite beverage, and let’s dive in!

Unpacking the Meaning and Objective of WMS

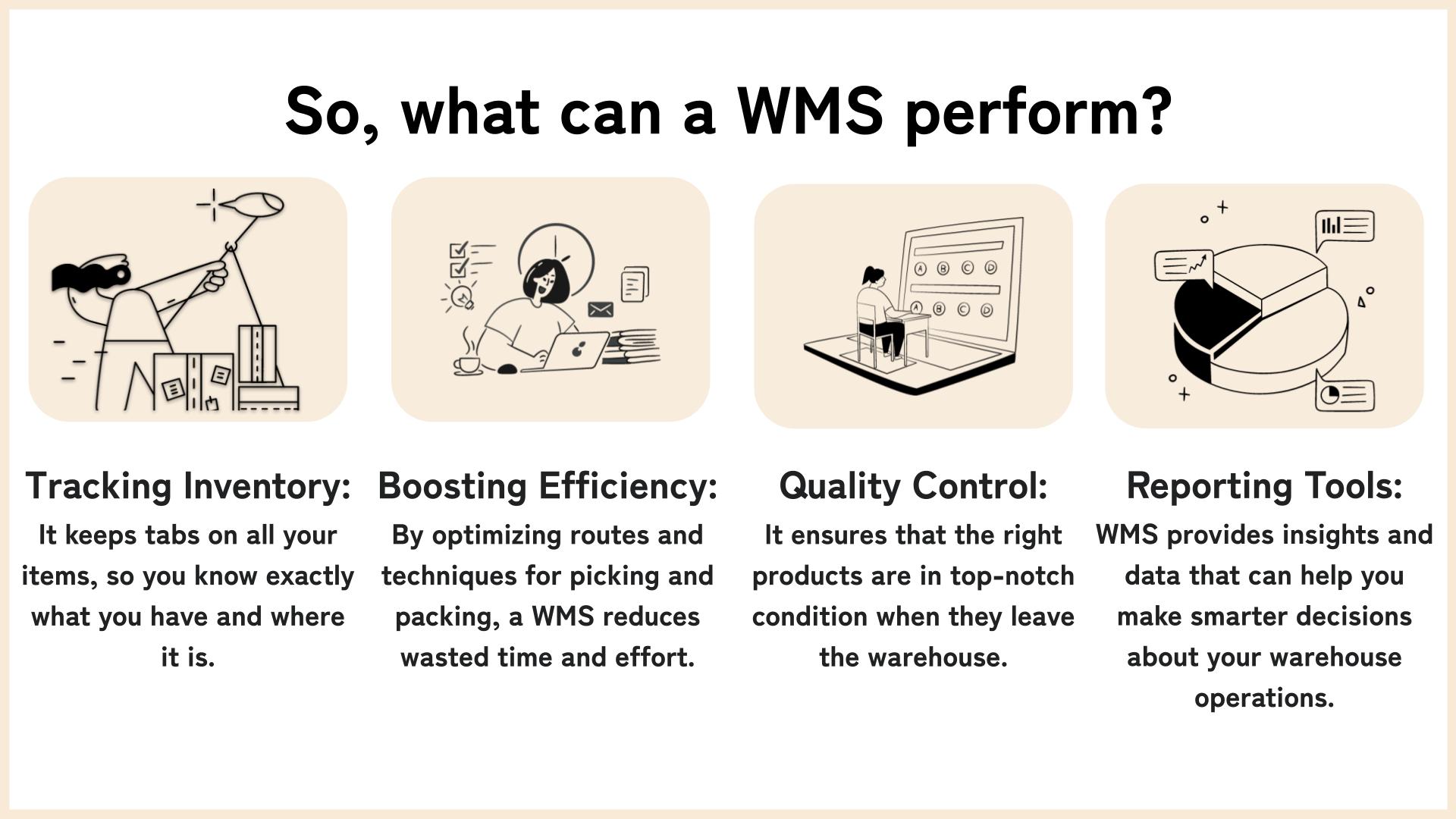

Think of a warehouse as a giant jigsaw puzzle, with pieces scattered everywhere. A Warehouse Management System (WMS) is essentially the picture on the puzzle box; it helps you organize all those pieces (your products) efficiently.

In technical speak, a WMS is a software solution designed to support and optimize warehouse operations from the moment goods enter your warehouse until they leave.

The main objective here is pretty straightforward – streamline all your warehouse processes to save time, reduce errors, and cut costs.

This includes everything from inventory tracking and picking orders to shipping and receiving goods.

The Benefits of Using a Warehouse Management System (WMS)

Streamlining Operations: The Efficiency Engine

Imagine if every process in your warehouse moved as seamlessly as your favorite playlist. That's your operation on WMS.

By automating tasks and optimizing workflows, a WMS cranks up the efficiency dial, making sure every action from receiving to shipping is a hit.

Inventory Visibility: No More Hide and Seek

Gone are the days of playing detective with missing stock. A WMS provides real-time inventory tracking, offering you a crystal-clear view of what's in stock, where it's located, and how much you have.

This means you can wave goodbye to overstocking or stockouts and say hello to just the right amount of inventory.

Deskera states that using integrated order processing for their inventory system can boost productivity by 25%, space consumption by 20%, and stock use efficiency by 30% for businesses.

Accuracy: Say Bye to Blunders

Mistakes in the warehouse can be costly and, frankly, embarrassing. With a WMS, the accuracy of your orders goes through the roof.

From ensuring the right item is picked to verifying that shipments are complete and correct, a WMS helps you maintain your reputation by keeping blunders at bay.

Customer Satisfaction: Deliver Smiles, On Time

Happy customers are repeat customers. A WMS not only helps you get orders out the door faster but also with higher accuracy.

This means your customers get exactly what they ordered, on time, boosting satisfaction and loyalty.

In the age of instant gratification, a WMS could be your secret weapon in winning the customer service game.

Scalability: Grow Without the Growing Pains

As your business expands, so do the complexities of managing your operations. A WMS grows with you, offering scalable solutions that adapt to your changing needs.

Whether it’s increasing storage, handling more orders, or adding new product lines, a WMS ensures your expansion is smooth and painless.

Data-Driven Decisions: The Power of Insight

In the dark about how your warehouse performs? A WMS sheds light by providing valuable data and insights.

From identifying trends to highlighting inefficiencies, this information is gold in strategizing improvements, reducing costs, and enhancing overall performance.

Saving Green by Going Green

By optimizing storage and reducing waste, a WMS can have a surprisingly positive impact on your carbon footprint.

Efficient route planning means less energy use, and better inventory management leads to less waste. Who knew saving the planet could also save you money?

Understanding the Process Cycles

To get a clearer picture, let’s talk about the major cycles in warehouse management:

- Receiving Goods: This is step one, where your warehouse receives stock and gets it ready for storage.

- Storage: Now, you need a smart plan to store these items. It’s like playing Tetris – you want to utilize your space best and keep things organized.

- Picking: When an order comes in, you pick the items from their storage spots.

- Packing: Time to pack those items up safely for their journey to the customer.

- Shipping: The last step is getting the order out the door and on its way.

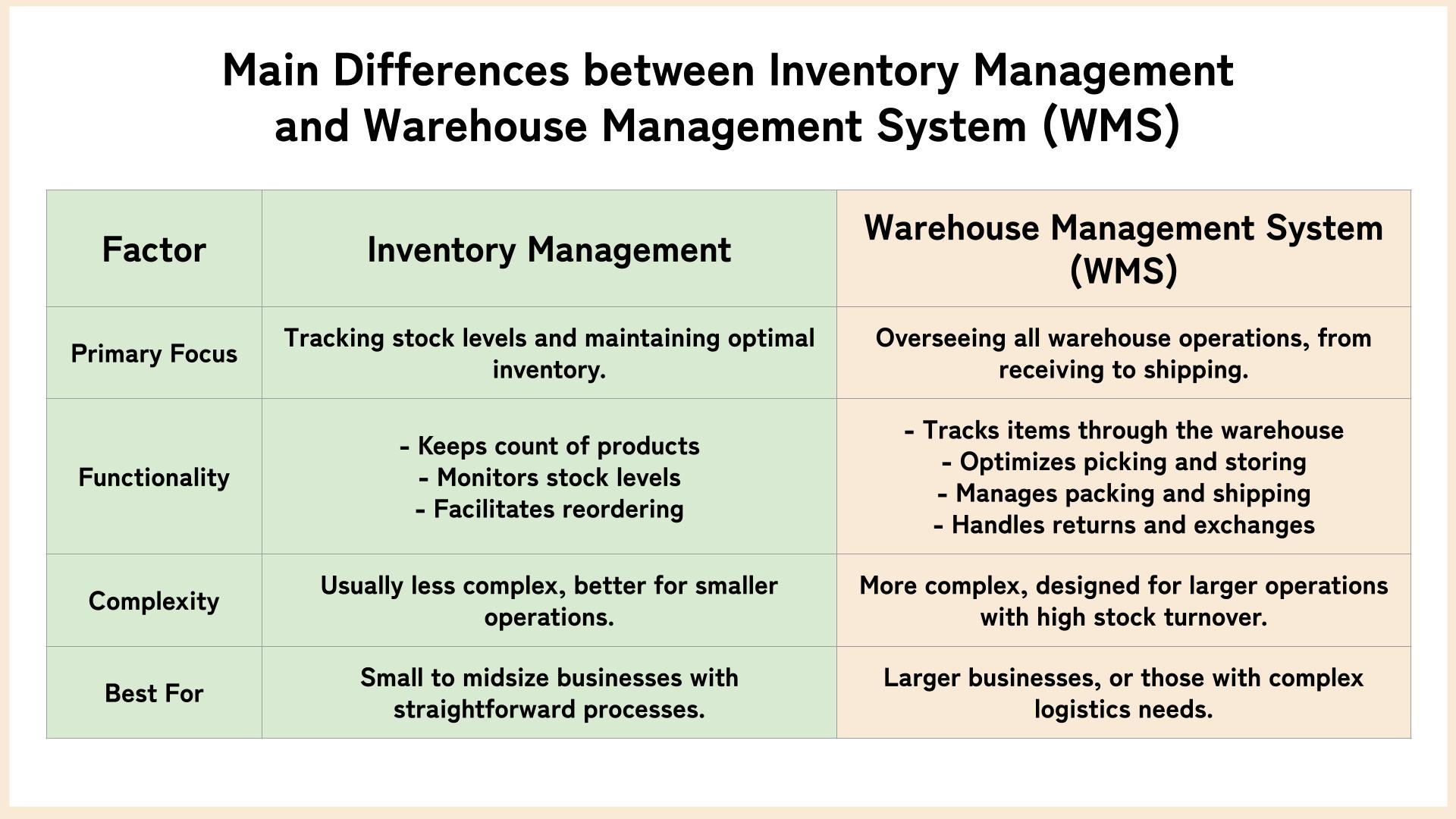

WMS vs. Inventory Management: What’s the Difference?

Easy confusion here, but let’s clear it up. First up is inventory management, the quarterback calling the plays for your product levels.

It's a simpler, less extensive system that focuses on tracking the number and value of items in your business—basically, a very skilled accountant for your products.

It tells you what you have in store, how much of it is selling, and signals when it's time to restock.

On the other hand, a WMS doesn't just keep count; it's the coach with a full-blown strategy.

This software oversees and orchestrates every move within your warehouse's four walls.

From the moment goods enter the dock to the time they're shipped out, the WMS is on top of it, ensuring that every step is as smooth as a well-oiled conveyor belt.

Let's break down these concepts into a handy, easy-to-understand table to highlight their main functions and differences:

In simple terms, inventory management is about what you have, and WMS is about everything happening in your warehouse.

Strategies to Implement WMS

Implementing a WMS isn’t a one-size-fits-all deal. However, here are some universal tips:

1. Define Clear Objectives

Start with a clear understanding of why you are implementing a WMS. What issues are you aiming to resolve? Is it to reduce picking errors, increase inventory visibility, or improve shipping times?

Setting specific goals will guide your decisions throughout the process and help measure success post-implementation.

2. Assemble the Right Team

Pull together a project team that includes stakeholders from different departments such as IT, warehouse operations, and finance.

Each member brings a unique perspective and contributes to comprehensive planning and smoother problem-solving.

3. Choose the Right System

Selecting a WMS that fits your specific needs is crucial. Do thorough research, compare different systems, and consider your current and future requirements.

Don’t shy away from asking for demos and customer references from WMS providers.

4. Map Out Current Processes

Take a deep dive into your existing workflow and identify inefficiencies or gaps.

This audit will help you understand which processes you want to enhance and provide a baseline for configuring your new WMS.

5. Clean Your Data

Data is the lifeline of a WMS. Ensure that the data you will migrate into your new system is clean, accurate, and organized.

This might be a good time for a data cleanup—eliminate obsolete inventory records, update supplier and customer information, and ensure consistency across data fields.

6. Customization and Integration

Work with your vendor to customize the WMS so that it seamlessly aligns with your business operations.

Ensure the system integrates well with other business management software you use, such as ERP or CRM systems.

7. Comprehensive Training

Preparation is key to adoption, so invest in thorough training for all users before going live.

Training should encompass both the technical aspects of the software and the best practices for leveraging its features to optimize warehouse processes.

8. Go Live with a Phased Approach

Roll out the WMS in phases. Start small—perhaps with a single product line or department.

This approach lets you tackle unforeseen challenges more manageably and refine the system before a full-scale launch.

9. Monitor, Evaluate, and Adapt

After going live, actively monitor the system’s performance and gather feedback from users. Evaluate this information and be prepared to make necessary adjustments.

Continuous improvement will help you maximize the benefits of your WMS.

Choosing the Right Software

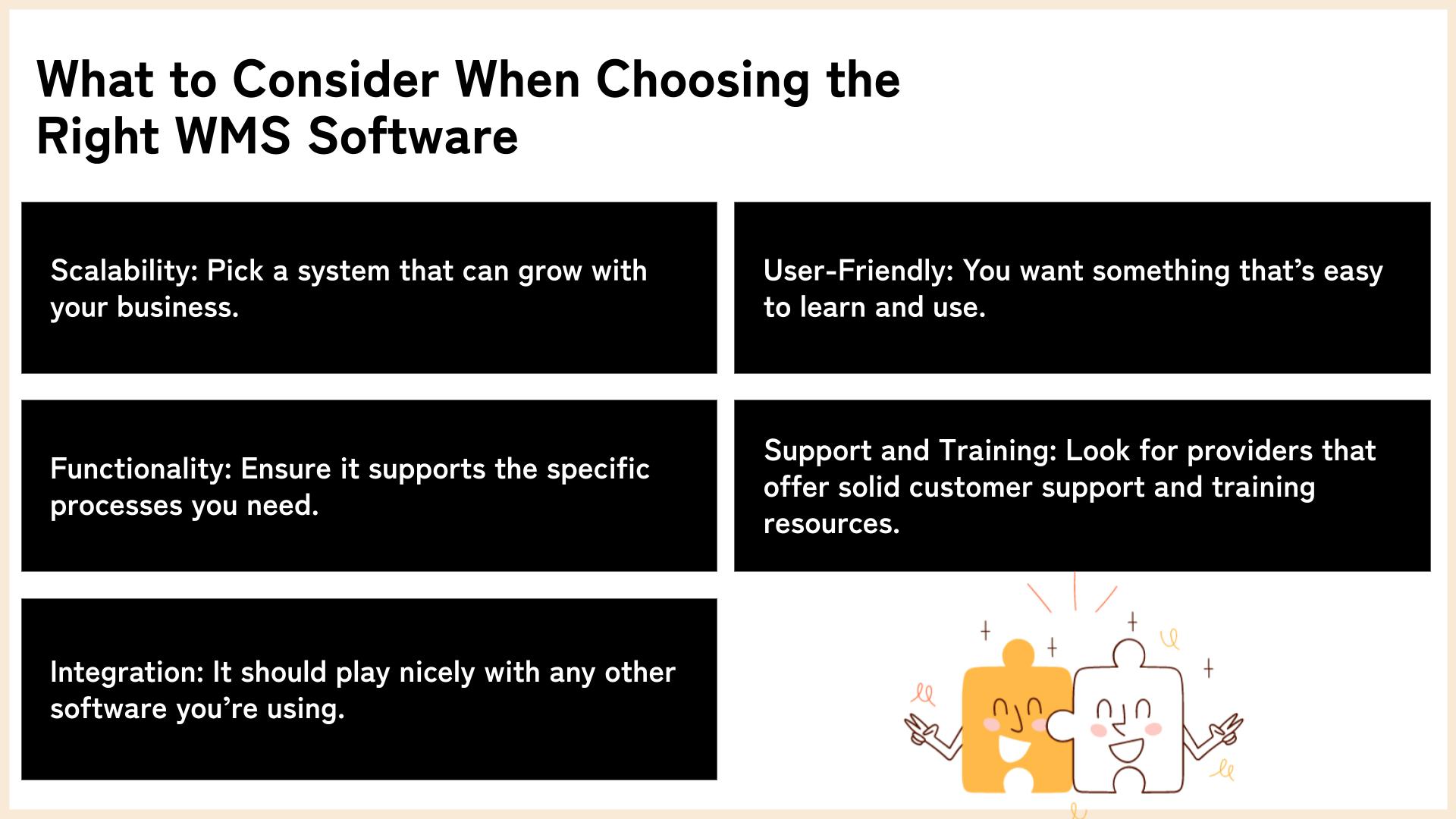

Selecting the right WMS can feel like finding a needle in a haystack. Here are some pointers to help you make that choice:

1. Assess Your Needs

Before anything else, take a step back and evaluate what you need from a WMS. Are you looking to improve inventory accuracy? Do you need real-time data tracking?

Understanding your specific requirements will help narrow down your options to systems that offer the features that matter most to your business.

2. Consider Scalability

Your business isn't static, and your WMS shouldn't be either. Opt for a system that not only meets your current needs but can grow with you.

Scalability is key, ensuring that as your business expands, your WMS will be able to handle increased volume, additional warehouses, or evolving business models without breaking a sweat.

3. Evaluate User-Friendliness

A system could have all the bells and whistles, but if it's not user-friendly, it can become more of a hindrance than a help.

Look for a WMS with an intuitive interface that won't leave your team scratching their heads.

Remember, the faster your team can adapt, the quicker you'll see the benefits.

4. Integration Capabilities

In today's interconnected world, your WMS should play nice with other systems you're using, whether it's your ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), or e-commerce platforms.

Seamless integration ensures a smooth flow of data across your business, eliminating manual data entry errors and inefficiencies.

5. Support and Training

Investing in a WMS is not just about the software itself but also about the ongoing support and training provided.

Choose a vendor known for excellent customer service and offers comprehensive training programs.

Effective support can drastically reduce downtime and ensure your operations continue to run smoothly.

6. Consider Cost vs. Value

While cost is certainly a factor, it's more important to consider the value the WMS brings to your operations.

A higher upfront cost might be worth it if the system offers significant efficiency gains, reduces errors, or improves customer satisfaction.

Additionally, explore the pricing structure—whether it's a one-time purchase, monthly subscription, or based on transaction volume, and ensure it aligns with your budget.

Conclusion

A well-implemented WMS can transform your warehouse from a chaotic storage space to a well-oiled machine.

Remember, the key is not just to choose any system but the right system that fits your unique business needs.

Take your time, do your homework, and don’t be afraid to ask for demos. Entering the world of warehouse management systems is a big step towards smarter, more efficient operations.

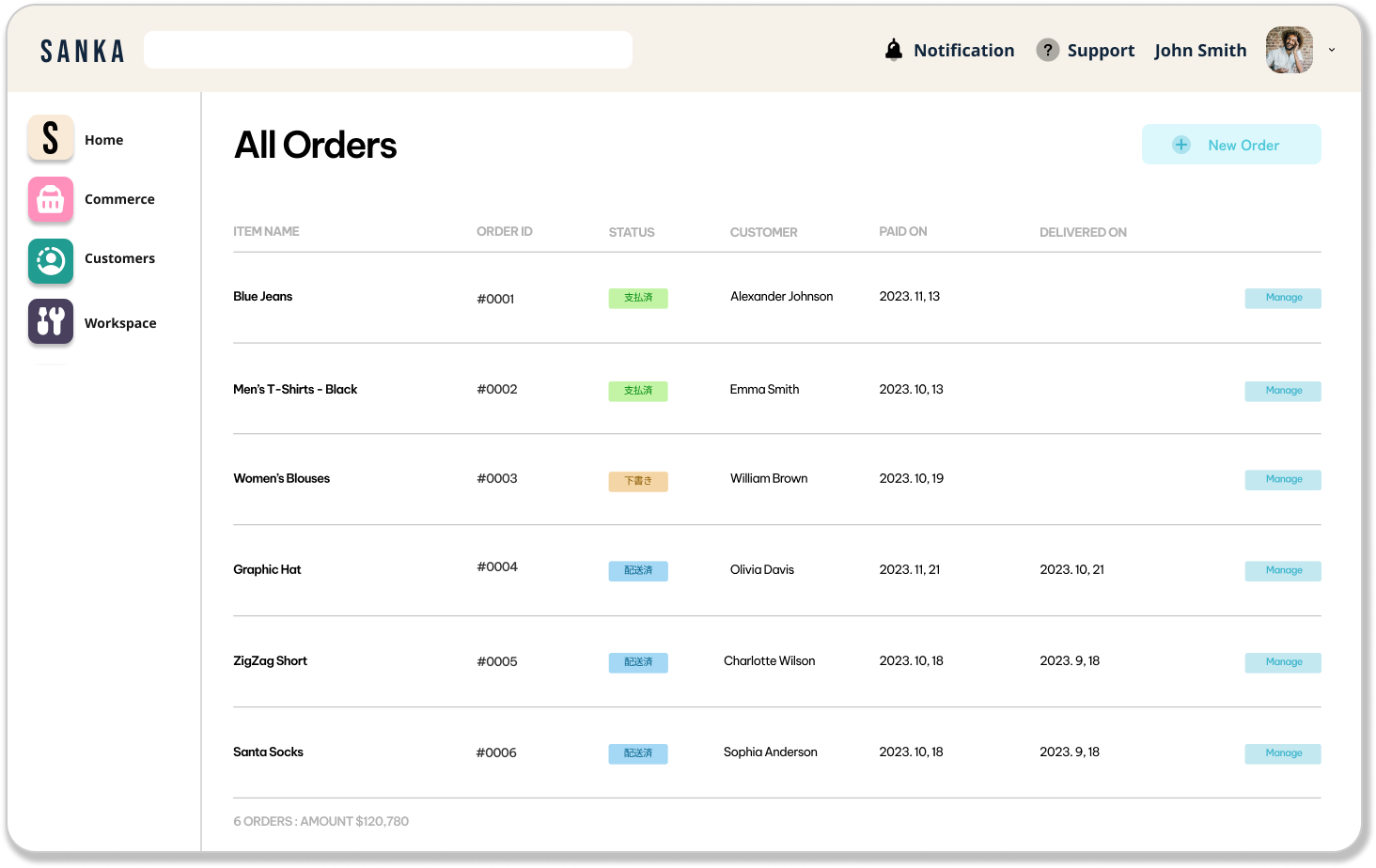

But before we bid you farewell, let us leave you with a final thought. In your search for the perfect WMS sidekick, look no further than Sanka, your all-in-one commerce management platform.

As you peruse the horizon of WMS options, consider how Sanka could revolutionize your commerce management.

With its unbeatable ROI, commitment to customer satisfaction, and a user-friendly interface, Sanka stands as a stalwart companion in your business adventure.

Ready to take the leap? Embrace Sanka, never just a system, but a partner in your quest for warehouse wizardry.

Until next time, may your inventory be accurate and your orders fulfilled with precision. Happy warehousing!